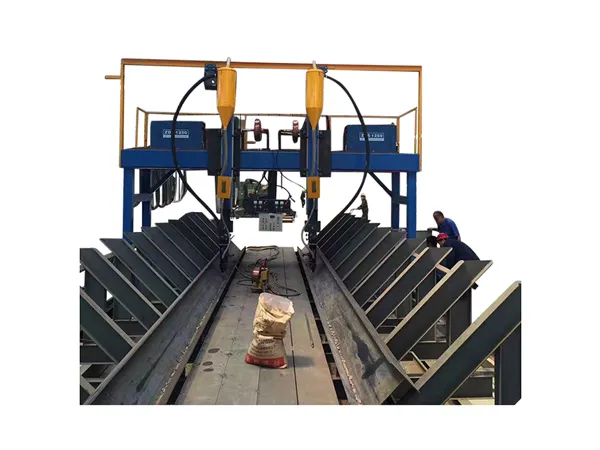

Are you preparing to install a new gantry welding machine? A proper installation is crucial for ensuring the machine’s performance, safety, and longevity. This comprehensive guide will walk you through the entire Gantry welding machine installation process step-by-step, providing you with the essential information you need to get your machine up and running smoothly.

A gantry welding machine, often used for heavy-duty fabrication, requires a precise and meticulous setup. Skipping steps or making assumptions can lead to operational issues and safety hazards. By following this detailed Gantry welding machine installation manual, you can avoid common pitfalls and ensure a successful installation.

Before you even start unpacking your machine, proper site preparation is key. This stage is a critical part of the Gantry welding machine installation process.

Location Selection: Choose a flat, level, and strong foundation that can support the machine's weight and the parts being welded. Ensure the area is free from dust, moisture, and excessive vibration.

Power and Utilities Check: Confirm that the power supply meets the machine's requirements. Verify the availability of compressed air and any other necessary utilities. This is a common point of failure, so double-checking is crucial.

Unpacking and Inventory: Carefully unpack all components and use the packing list to verify that all parts, bolts, and accessories are present. Report any missing or damaged items immediately to the supplier.

This is where the physical assembly begins. The proper erection of the gantry is fundamental to the stability of the entire system.

Foundation and Base: Securely fasten the machine's base rails to the pre-prepared foundation using anchor bolts. Use a level to ensure the rails are perfectly aligned and level. Any misalignment here will impact the welding precision.

Gantry Beam Assembly: Carefully lift and place the main gantry beam onto the base rails. Follow the instructions in the Gantry welding machine installation guide to correctly secure the beam. This often involves tightening large bolts to specific torque specifications.

End Carriages and Trolleys: Mount the end carriages and welding trolleys onto the gantry beam. Ensure they move freely and smoothly along the beam without any binding or resistance.

With the gantry structure in place, it's time to install the welding equipment and connect the controls.

Mounting the Welding Head: Attach the welding head or heads to the trolley. This is a delicate part of the Gantry welding machine installation process, as the alignment of the welding torch is paramount.

Cable Management: Route all power cables, control cables, and pneumatic hoses neatly and securely. Use cable trays and guides provided with the machine to prevent them from getting tangled or damaged.

Connecting the Control Panel: Connect the main control panel to the machine's power and control systems. This step requires careful adherence to the wiring diagrams in the Gantry welding machine installation manual.

The final stage is to test the machine and ensure everything is working as it should.

Mechanical and Electrical Check: Double-check all bolted connections for tightness. Perform a final visual inspection of all wiring.

Functional Test: Power up the machine and perform a series of dry runs. Test the movement of the gantry, the welding heads, and all safety features.

Initial Welding and Calibration: Conduct a few test welds. Calibrate the welding parameters (voltage, current, travel speed) to match your specific application. This final calibration is what makes your Gantry welding machine installation a success.

By meticulously following this detailed Gantry welding machine installation process, you can ensure that your new equipment operates safely and efficiently from day one. A proper installation not only guarantees high-quality welds but also significantly extends the lifespan of your investment. If you have any questions, always refer back to your official Gantry welding machine installation manual or consult with a qualified technician.

No. 1 Intersection of Chuangye Avenue and Weilai Avenue,

Yiyang County,Luoyang City, Henan Province, China

+86 400-0379-069

Copyright © 2023 An Automated Welding and Cutting Equipment Manufacturer Focusing on Welding Column Boom and Welding Rotator | All Rights Reserved Technical support: ShangXian