This product is a LTHS-E flux recovery and conveying machine, which is suitable for the cross-operating machine and various submerged arc welding projects that need to recycle flux.

This product is a LTHS-E flux recovery and conveying machine, which is suitable for the cross-operating machine and various submerged arc welding projects that need to recycle flux.

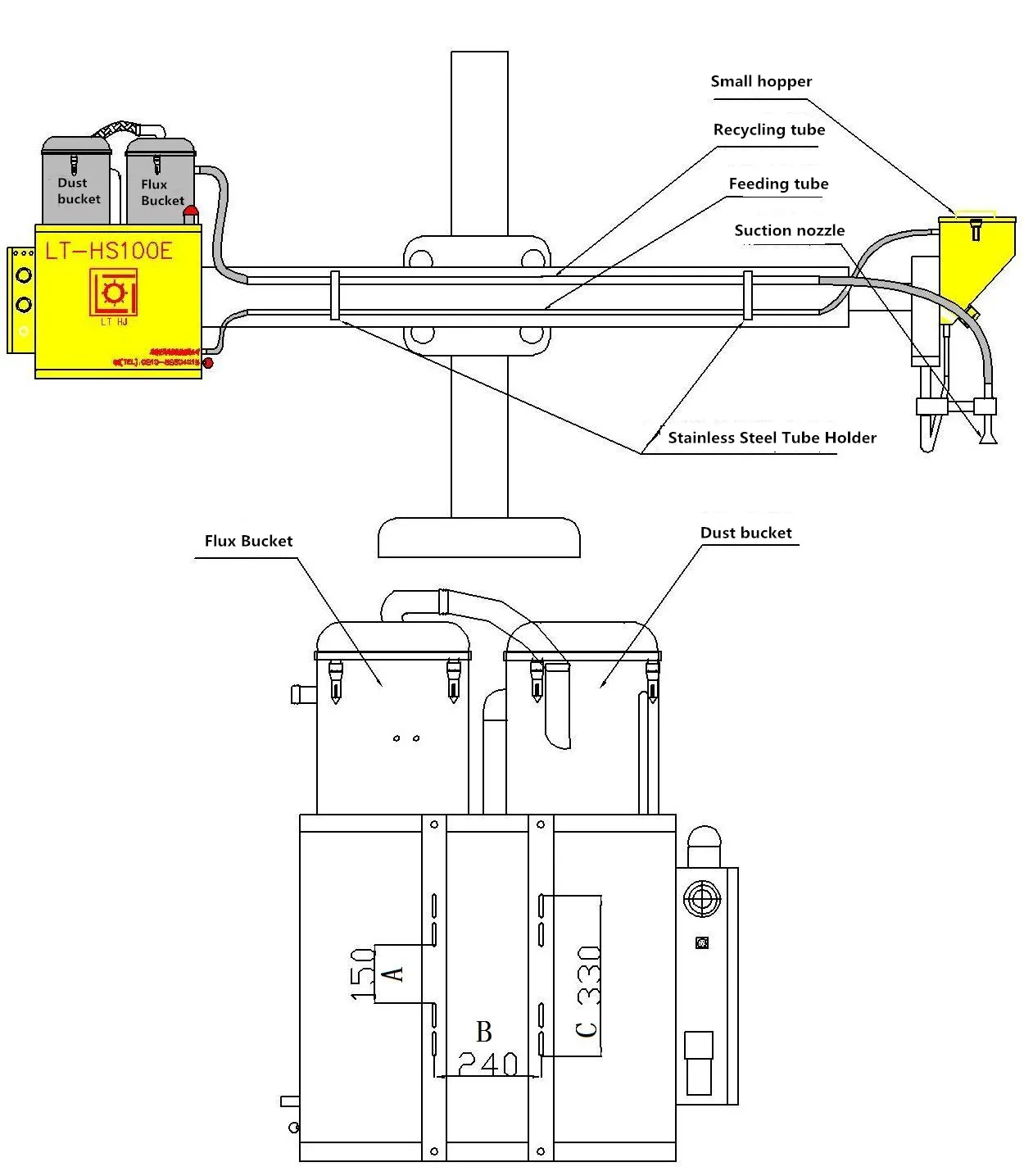

The complete set of equipment consists of a recycling conveyor body, a flux hopper, a stainless steel tube, a connecting hose and a suction nozzle. The recovery main unit is suspended and installed at the end of the cross arm. The flux hopper and the flux suction nozzle are installed on the welding head, and the middle is connected by a stainless steel tube and a hose (see the fourth item for installation). This constitutes a circulatory system for automatic flux delivery and unmelted flux recovery.

(1)working conditions

Relative humidity of air: The average daily temperature is not more than 25 ° C, and the average relative humidity of the wettest month is 90%.

(2)Working environment

Equipment should be placed in an explosive or corrosive industrial gas, water vapor, salt spray and chemical deposits that do not seriously harm or affect the normal use of the equipment, and should be kept away from severe vibration and bumps.

(1)The imported air pump assembly can be used for voltages between 240V and 480V (the number of voltages varies depending on the connection method.

(2)LTHS-E2 type is E1 type upgrade product, using pneumatic actuator to control butterfly valve, reliable and durable. Until the flux in the main unit starts to alarm at about 10KG, the feeding will be suspended for 45 seconds, so that the recovered flux enters the transfer tank and is sent again. The flux in the small hopper can be maintained and will not stop.

(3)The use of high-precision capacitive sensing switch induction welding dose, to achieve alarm function, good sensitivity, high accuracy, stable and reliable work, suitable for the harsh environment of flux.

(4)The bottom is equipped with a discharge valve, which is controlled by the side discharge handle of the machine. The flux type can be changed at any time according to the welding demand. The bottom is not flat and the shape is beautiful. It can be hung or laid flat.

(5)According to customer needs to add high quality and stable silicone heating and insulation system (temperature 0 ° C -150 ° C) and far infrared heating system.

(6)The flux capacity of LT-HS100E2 flux barrel is ≤50kg.

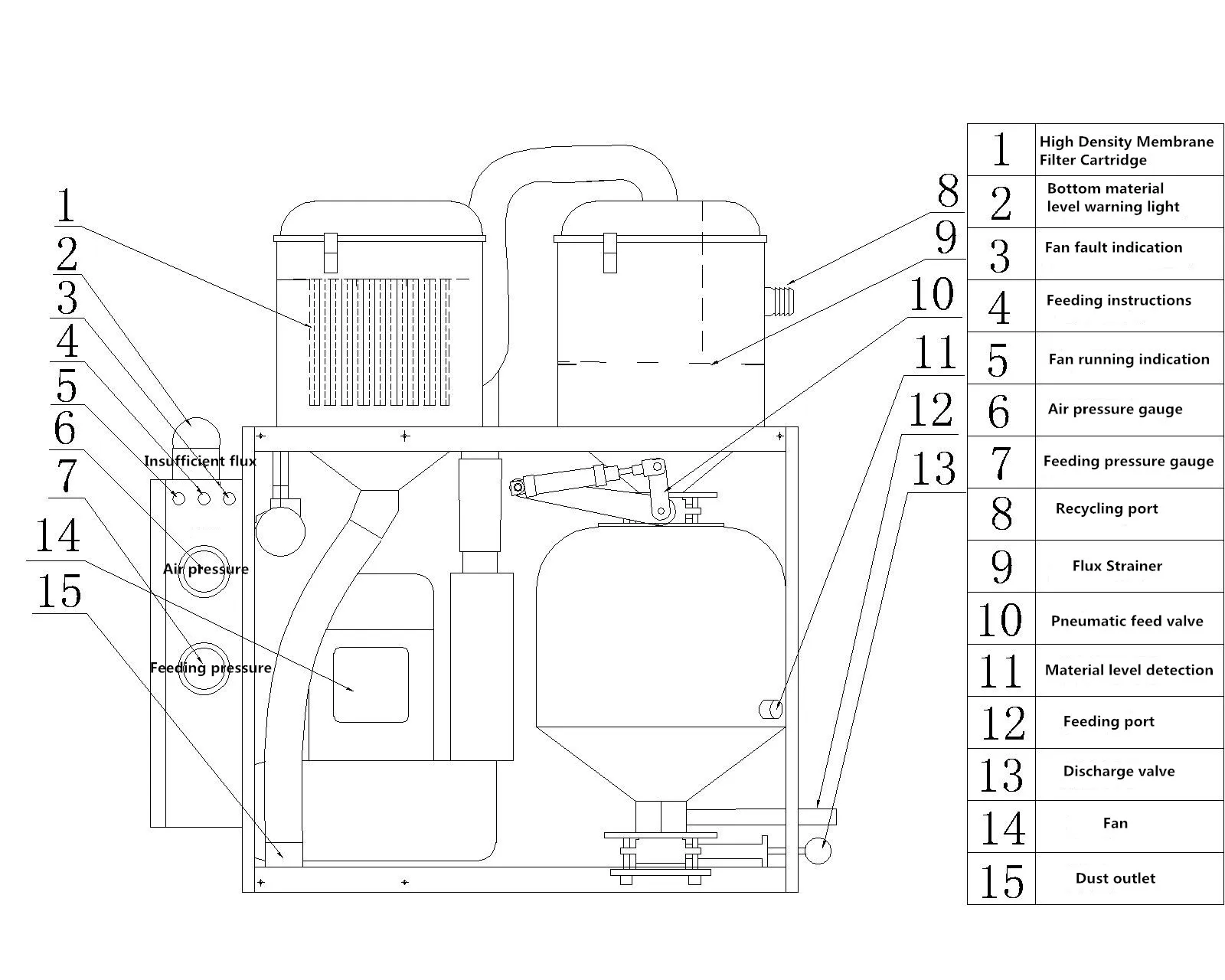

(7)The dust-removing bucket uses a high-density membrane filter to efficiently filter dust, so that the discharged gas is environmentally friendly.

1. Hanging type: The installation method of this machine should be determined according to the structure of the user's cross arm. Please refer to the following figure.

1) As shown in the figure, at the installation of the cross arm of the manipulator, as shown in the figure, A=150mm, B=240mm, C=330mm, punch the hole of M10, fix the main body on the cross arm with screws, and automatically weld the flux bucket. Fit) Installed in the appropriate position on the welding head.

2) Fix the stainless steel pipe bracket on the cross arm and install the stainless steel pipe with outer diameter Φ38 and Φ25 on the bracket (stainless steel pipe needs to be provided by the user).

3) Connect the main machine, stainless steel tube and nozzle with rubber hose. The nozzle is fixed by the nozzle bracket.

4) The pneumatic flux bucket (optional) is connected to the main unit by two Φ8 gas pipes. The Lincoln-type pneumatic flux hopper (optional) is connected to the main unit by a Φ8 gas pipe.

5) The 0.8Mpa air source is connected to the oil-water separator, and the remote control is connected to the remote control interface behind the host. The power supply 4 is connected and the installation is completed.

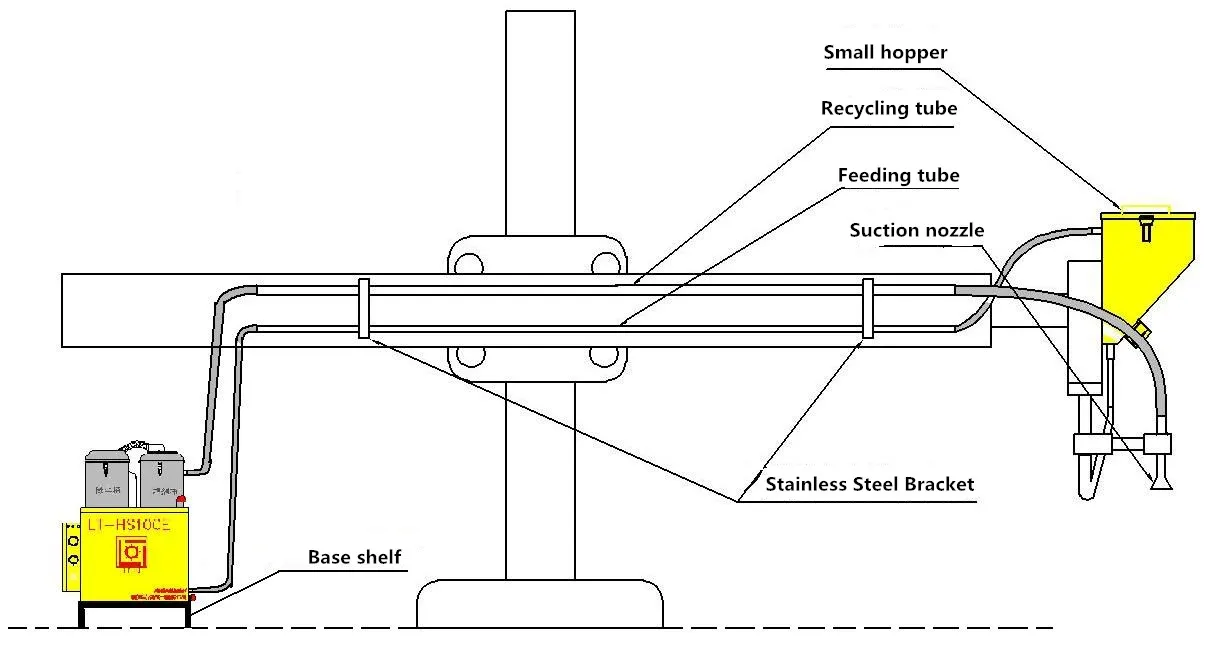

2. Floor-standing: installation as shown below

|

Mode |

LTHS100E2 |

LTHS100+E2 |

LTHS150E2 |

LTHS150+E2 |

|

Operating Voltage |

380V |

380V |

380V |

380V |

|

Motor Power |

3KW |

3KW |

5.5KW |

5.5KW |

|

Capacity |

50KG |

100KG |

50KG |

100KG |

|

Working negative pressure Kpa |

0.22-0.24 |

0.24-0.26 |

0.22-0.24 |

0.24-0.26 |

|

Horizontal recovery distance |

12-25m |

16-30m |

12-25m |

16-30m |

|

Horizontal conveying distance |

12-25m |

16-30m |

12-25m |

16-30m |

|

Vertical recovery distance |

6-8m |

7-9m |

6-8m |

7-9m |

|

Air source pressure Mpa |

0.4-0.6 |

0.4-0.6 |

0.4-0.6 |

0.4-0.6 |

|

Recovery rate |

8-15kg/min |

8-15kg/min |

8-15kg/min |

8-15kg/min |

|

Delivery rate |

2-20kg/min |

8-15kg/min |

8-15kg/min |

8-15kg/min |

|

Net weight KG |

150KG |

|

155KG |

|

|

Dimensions mm |

1100*500*1500 |

|

|

|

|

NO. |

Name/Model |

Quantity |

Note |

|

1 |

LTHS-E recycling conveyor |

1 |

|

|

2 |

Diameter 38 rubber tube |

1.7m+1m |

|

|

3 |

Diameter 25 rubber tube |

1.7m+1m |

|

|

4 |

Stainless steel tube holder |

3 |

|

|

5 |

Aluminum casting nozzle |

1 |

|

|

6 |

Nozzle fixing bracket |

1 |

|

|

7 |

Remote control |

1 |

|

|

8 |

Instruction manual |

1 |

|

|

9 |

Certificate |

1 |

|

|

10 |

Heating and insulation system |

Optional |

|

|

11 |

Universal nozzle bracket |

Optional |

|

|

12 |

Pneumatic bucket |

Optional |

|

|

13 |

Floor stand |

Optional |

|

No. 1 Intersection of Chuangye Avenue and Weilai Avenue,

Yiyang County,Luoyang City, Henan Province, China

+86 400-0379-069

Copyright © 2023 An Automated Welding and Cutting Equipment Manufacturer Focusing on Welding Column Boom and Welding Rotator | All Rights Reserved Technical support: ShangXian