POWERPLUS® 1000HD is designed for constant current and constant voltage submerged arc welding. The welding arc is stable over a wide range of parameters and the output can be precisely controlled. The power source is combined with the Lincoln Electric Rover™ Tractor to create a robust automatic welding package.

POWERPLUS® 1000HD is designed for constant current and constant voltage submerged arc welding. The welding arc is stable over a wide range of parameters and the output can be precisely controlled. The power source is combined with the Lincoln Electric Rover™ Tractor to create a robust automatic welding package.

POWERPLUS®1000HD is rugged and reliable to operate in the harshest welding conditions. It is often used for welding mild steel, low alloy steel, and stainless steel. The POWERPLUS®1000HD can also be used by itself for carbon arc gouging. It is used in many industries, such as shipbuilding, wind tower and pressure vessels.

Processes:Submerged Arc, Gouging

Wire Feeder Options:Rover™ Tractor

Required Options:Tractor, Control Cable, Welding Cable, Work Cable with Clamp, Track

Design Features

| Product Name | Product Number | Input Power |

Rated Output

Current/Voltage/Duty Cycle

|

Input Current

@ Rated Output(KVA)

|

Output Range |

Dimensions

H*W*D

|

Net

Weight(kg)

|

| Powerplus®100HD | K60067-3* | 380-415V(±10%)/3PH/50HZ/60HZ |

1200A/44V/60%

1000A/44V/100%

|

69@100% | 200-1200A | 900*600*970 | 335 |

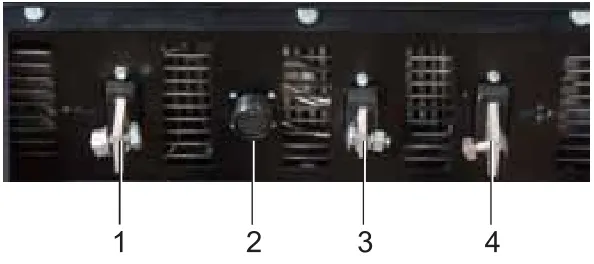

Front Panel

Output Stud

Back Panel

No. 1 Intersection of Chuangye Avenue and Weilai Avenue,

Yiyang County,Luoyang City, Henan Province, China

+86 400-0379-069

Copyright © 2023 An Automated Welding and Cutting Equipment Manufacturer Focusing on Welding Column Boom and Welding Rotator | All Rights Reserved Technical support: ShangXian