*Can be customized according to user requirements

Wind power generation Tower production line is a special equipment designed and produced by our company for the wind power industry.

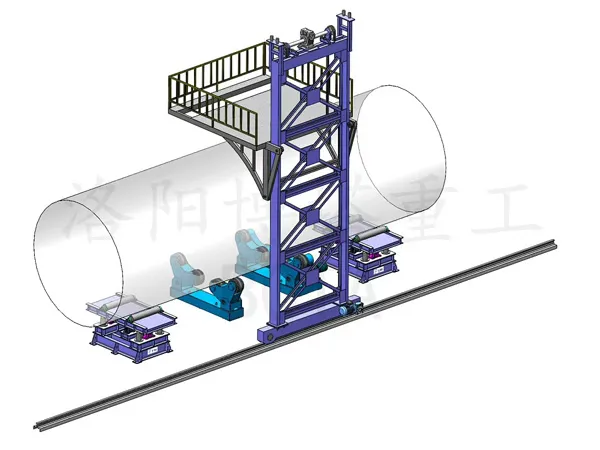

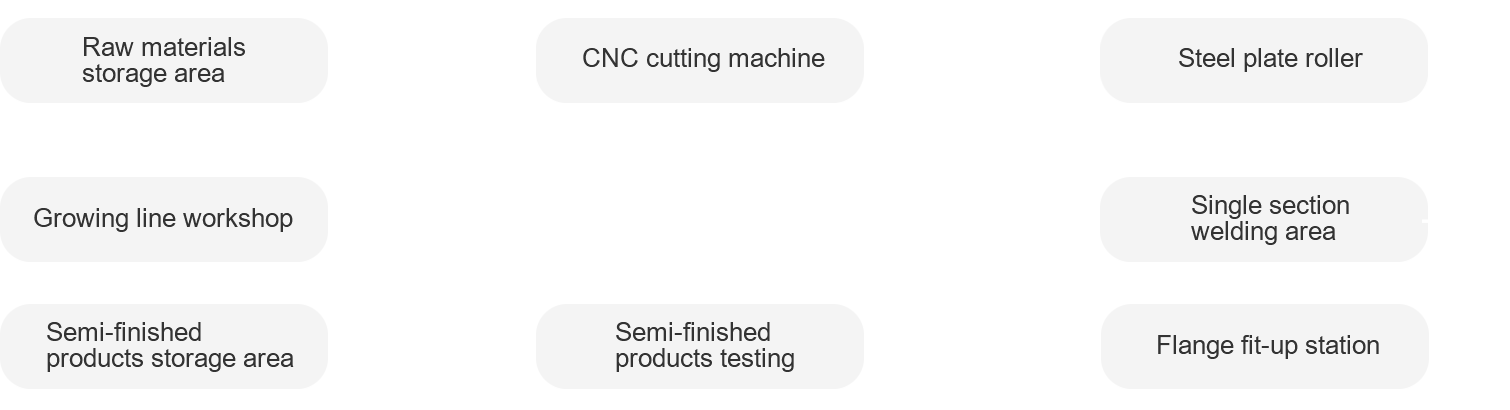

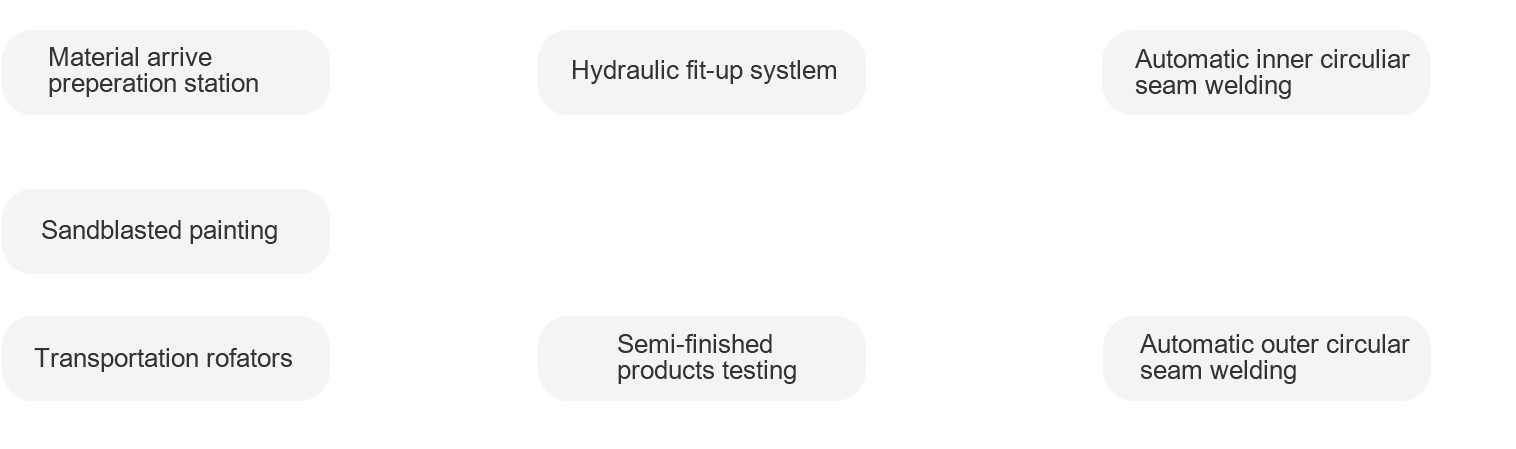

Mainly include: blanking and cutting equipment, cylinder longitudinal and circumferential seam welding equipment, cylinder joint hydraulic automatic assembly equipment, flange automatic welding equipment, automatic sandblasting and spraying equipment, Tower transfer equipment, etc.

A suitable layout can be designed according to the characteristics of the customer's workshop to make the whole production line smoother.

BOTA has been devoting itself to the R&D and application of the overall solution for the wind power tower automation and high-efficiency welding factory and the development and application of new technologies. We have mastered the development trend and direction of the industry from the successful application experience of automated welding factories in China and the new clean energy industry in the past ten years, as well as the process of growing and developing with industry elites, and integrated new welding technology equipment that is constantly improving, Under such continuous benign promotion of development, we are able to provide onshore wind power generation and offshore wind power Tower manufacturing enterprises with a whole-process plant solution of demand consultation, planning and design, manufacturing, installation and commissioning, and operation management.

The company is a professional enterprise engaged in the design and manufacture of welding equipment and welding automation planes. The welding equipment designed and manufactured is self-developed by absorbing the advantages of similar products at home and abroad and combining the requirements of multiple industries. It has the advantages of advanced technology, reliable quality, and easy operation. The company has a wealth of professional and technical personnel in welding, mechanical and electrical and mechatronics. We have been focusing on welding automation equipment for many years and have achieved thousands of field solutions.

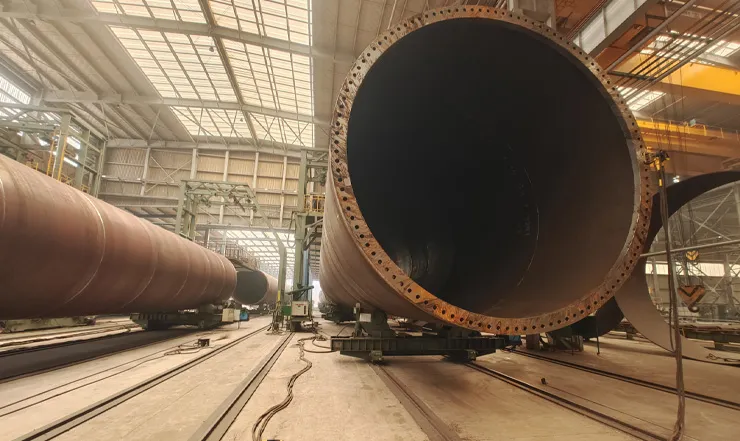

The production line incorporates material handling equipment, such as conveyors, cranes, or automated guided vehicles (AGVs), to transport steel plates and wind tower sections to different workstations.

The production line includes multiple welding stations where various welding processes, such as submerged arc welding (SAW) or flux-cored arc welding (FCAW), are performed to join the steel plates and create the cylindrical wind tower sections.

Advanced welding manipulators, welding column booms, or robotic welding systems may be used to position the welding equipment precisely along the weld seam, ensuring consistent and accurate welding.

Prior to welding, the edges of the steel plates are prepared, beveled, and tack-welded to create a suitable weld joint geometry and ensure proper weld penetration.

Throughout the production line, various quality control measures, including non-destructive testing (NDT) methods and visual inspections, are employed to verify weld quality, dimensions, and alignment.

As the production line progresses, the tower sections are assembled and aligned to ensure proper fit and dimensional accuracy.

At specific stations, the tower sections are connected to each other, and flanges are welded to provide attachment points for the nacelle and blades.

For larger wind turbine towers or specific project requirements, post-weld heat treatment may be conducted to relieve residual stresses and enhance the weld's mechanical properties.

After welding, wind tower sections may undergo surface treatment, such as painting or coating, to protect them from corrosion and environmental exposure.

Before the completed wind tower sections leave the production line, they undergo final inspection and testing to ensure they meet the required quality and safety standards.

We can provide design, manufacture, installation and after-sales service:

1. Design and planning service for the whole plant process flow of the wind tower welding production line.

2. Whole plant equipment manufacturing, installation and commissioning training service for wind tower welding production line.

3. Long-term and perfect after-sales service for the whole plant equipment of the wind tower welding production line.

Provide whole plant solutions for pipelines, steel structures, pipe structures, wind power towers, and pressure vessels for customers at home and abroad.

Professional welding column boom manufacturer

To provide you with a one-stop welding & cutting solution

LEAVE MESSAGE →No. 1 Intersection of Chuangye Avenue and Weilai Avenue,

Yiyang County,Luoyang City, Henan Province, China

+86 400-0379-069

Copyright © 2023 An Automated Welding and Cutting Equipment Manufacturer Focusing on Welding Column Boom and Welding Rotator | All Rights Reserved Technical support: ShangXian