Choosing the correct size and stroke for a welding column and boom manipulator is crucial for maximizing efficiency, quality, and safety in your welding operations. It essentially comes down to understanding the dimensions of your workpieces and the required welding processes.

Column (Vertical Travel/Lift): This refers to the vertical height the boom can extend up and down. It's often expressed as the "vertical reach" or "column stroke."

Boom (Horizontal Travel/Reach): This refers to the horizontal distance the welding head can extend outwards from the column. It's often expressed as the "boom reach" or "horizontal stroke."

Load Capacity: The maximum weight the end of the boom can safely support, including the welding head, wire feeder, flux recovery unit, camera systems, and any other accessories. This is critical for safety and operational stability.

Workpiece Dimensions (Length, Diameter, Height):

Maximum Length of Longitudinal Welds: The boom's horizontal stroke needs to be at least as long as the longest longitudinal weld you'll be performing. If you're welding very long components, you might consider a column and boom mounted on a travel car or even a gantry system for extended reach.

Maximum Diameter/Height of Circumferential Welds: The column's vertical stroke needs to accommodate the height of your largest workpiece when mounted on a positioner or turning rolls. The boom also needs to be able to reach the top and bottom of the circumference. Consider the "minimum height under boom" and "maximum height under boom" specifications.

Minimum Diameter/Height of Workpieces: Ensure the column and boom can retract sufficiently to work on smaller pieces without interference.

Welding Process and Equipment:

Weight of Welding Head and Accessories: Submerged Arc Welding (SAW) heads with flux hoppers and recovery systems are typically heavier than MIG or TIG setups. Factor in the weight of all attachments when considering the boom's load capacity.

Additional Equipment: If you're adding cross-slides, seam trackers, laser pointers, or operator platforms, these will add weight and potentially affect the required reach.

Shop Layout and Space Constraints:

Overhead Clearance: Ensure there's enough vertical space in your facility for the column to extend to its full height.

Floor Space: Consider the footprint of the column and boom, especially if it's a movable unit on rails.

Desired Level of Automation and Integration:

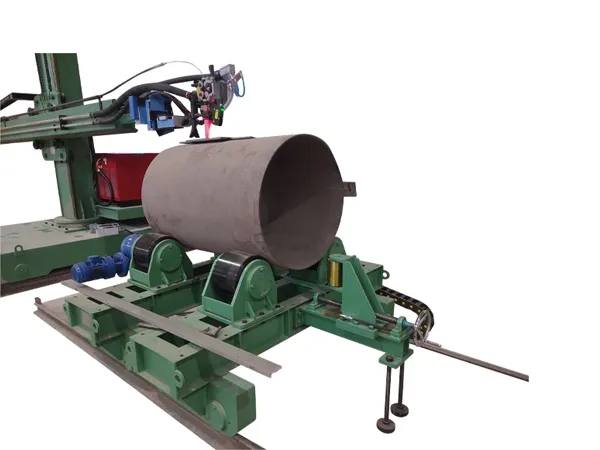

Automated Welding: If you plan on integrating with turning rolls, positioners, or robotic arms for fully automated welding, the column and boom needs to be compatible and have the necessary control interfaces.

Operator Access: Will an operator need a platform on the column for visual inspection or adjustments? This can influence the design and size.

Type of Welds:

Longitudinal Seams: Primarily utilizes the boom's horizontal travel.

Circumferential Seams: Utilizes both vertical and horizontal travel, often in conjunction with turning rolls or positioners.

Hard-to-reach areas: The flexibility of the boom's reach and the column's height are crucial.

Future Needs:

Consider potential future projects or larger workpieces you might encounter. Investing in a slightly larger system than your immediate needs can prevent costly upgrades later.

Measure Your Largest and Smallest Workpieces:

For cylindrical parts: Diameter and length.

For rectangular/irregular parts: Height, width, and length of the longest weld path.

Determine Welding Head Configuration: What welding process (SAW, MIG, TIG, etc.) will you be using, and what is the approximate weight of the complete welding head assembly with all necessary consumables and attachments?

Sketch Your Work Area: Draw a simple diagram of your shop floor, including the placement of positioners, turning rolls, and the intended working envelope of the column and boom. This helps visualize the required reach and clearance.

Calculate Required Strokes:

Vertical Stroke (Column):

Max Workpiece Height on Positioner+Clearance for Welding Head+Minimum Working Height

Don't forget to account for any offset from the center of the positioner to the weld line.

Horizontal Stroke (Boom):

Longest Longitudinal Weld Length+Overhang (if needed for torch clearance)

For circumferential welds, consider the radius of the largest workpiece and ensure the boom can reach across it.

Calculate Required Load Capacity: Sum the weight of your welding head, wire feeder, flux recovery unit, camera, cross-slide, and any operator platform or other accessories that will be mounted on the boom end.

Consult Manufacturer Specifications: Once you have your estimated requirements, compare them with the specifications provided by column and boom manufacturers. They typically list models with "column travel x boom travel" (e.g., 3m x 3m, 4m x 4m) and their corresponding load capacities.

Consider Options: Many manufacturers offer customization, motorized rotation, rail cars for extended travel, and various control systems. These options can significantly enhance the manipulator's versatility and productivity.

By carefully considering these factors and performing the necessary calculations, you can make an informed decision to choose a welding column and boom manipulator that perfectly suits your application and production needs.

No. 1 Intersection of Chuangye Avenue and Weilai Avenue,

Yiyang County,Luoyang City, Henan Province, China

+86 400-0379-069

Copyright © 2023 An Automated Welding and Cutting Equipment Manufacturer Focusing on Welding Column Boom and Welding Rotator | All Rights Reserved Technical support: ShangXian