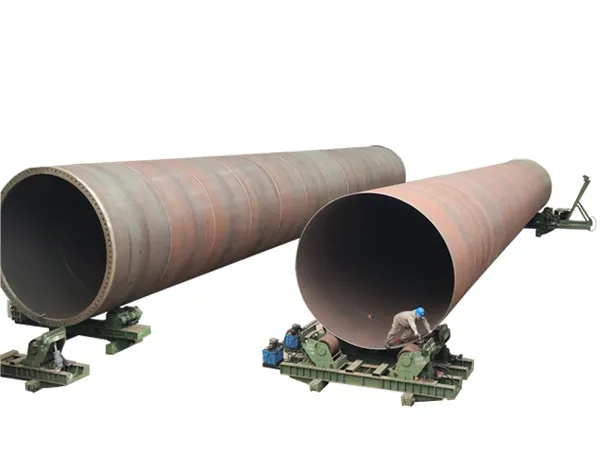

In shipbuilding,welding rotators are essential for handling heavy cylindrical and round components, improving weld quality, speeding up production, and ensuring worker safety.They are especially valuable for large-scale ship structures where precision and efficiency are critical.

Welding rotators play a crucial role in the shipbuilding industry, significantly improving the efficiency, quality, and safety of welding large cylindrical or asymmetrical components.

Positioning and Rotation: The most fundamental function is to accurately position and rotate heavy, often irregularly shaped, sections of a ship during the welding process. This ensures that welds can be performed in the optimal "downhand" position, which is the easiest and most efficient for welders, leading to better weld quality and faster completion times.

Handling Large and Heavy Components: Ship components like hull sections, storage tanks, pressure vessels, and large pipes can be incredibly heavy and cumbersome. Welding rotators, especially those with robust power and idler sections, are designed to safely support and maneuver these massive structures, eliminating the need for complex and often dangerous crane operations for repositioning during welding.

Improved Weld Quality: By providing stable and controlled rotation, rotators enable welders to maintain a consistent torch angle, travel speed, and arc length. This consistency is vital for producing high-quality, uniform welds with fewer defects, which is critical for the structural integrity and longevity of a ship.

Increased Welding Speed and Efficiency: Downhand welding is significantly faster than welding in other positions (horizontal, vertical, overhead). By continuously presenting the weld joint in the downhand position, rotators dramatically increase welding speed and reduce the overall time required for fabrication. This translates to higher productivity and cost savings.

Enhanced Welder Safety and Comfort: Operating large ship components can be hazardous. Rotators reduce the physical strain on welders by minimizing the need for awkward postures or reaching. They also create a safer working environment by keeping the heavy workpiece securely held and rotating it smoothly, reducing the risk of accidents associated with manual manipulation or unstable positioning.

Automation and Integration: Modern welding rotators can be integrated with automated welding systems, such as submerged arc welding (SAW) or gas metal arc welding (GMAW) processes. This allows for even greater precision, speed, and consistency, further optimizing the shipbuilding process.

Versatility for Various Ship Components: While commonly associated with cylindrical parts, rotators can be adapted with specialized fixtures to handle a variety of ship components, including conical sections, flat panels (using tilting rotators), and other non-standard shapes, making them highly versatile tools in a shipyard.

In essence, welding rotators are indispensable for efficient and high-quality fabrication of ships, contributing significantly to the structural integrity and timely delivery of these complex vessels.

No. 1 Intersection of Chuangye Avenue and Weilai Avenue,

Yiyang County,Luoyang City, Henan Province, China

+86 400-0379-069

Copyright © 2023 An Automated Welding and Cutting Equipment Manufacturer Focusing on Welding Column Boom and Welding Rotator | All Rights Reserved Technical support: ShangXian