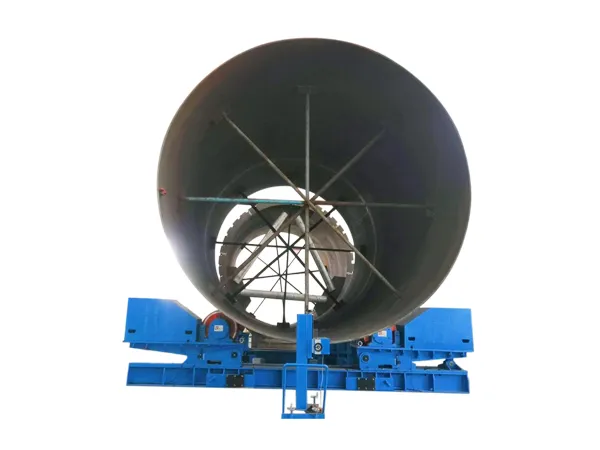

Welding rotators are a type of material handling equipment used in welding processes, particularly for the fabrication of cylindrical workpieces such as pipes, tanks, and pressure vessels. These devices are designed to rotate the workpiece during welding, providing a more efficient and controlled welding environment.Choosing the right welding rotator manufacturer is crucial to ensuring the quality and performance of your welding equipment.

Reputation and Experience

Look for manufacturers with a good reputation in the welding industry. Check reviews, testimonials, and ask for references.

Consider the manufacturer's experience in producing welding rotators. More experienced manufacturers often have a better understanding of design and manufacturing challenges.

Quality of Products

Evaluate the quality of the welding rotators they produce. Look for manufacturers who use high-quality materials and adhere to industry standards and certifications.

Consider the durability, reliability, and overall performance of their products.

Customization Options

Assess whether the manufacturer offers customization options to meet your specific welding needs. A manufacturer that can tailor their products to your requirements is valuable.

Technical Support and Training

Check if the manufacturer provides technical support, training, and documentation for their welding rotators. This is essential for efficient operation and maintenance of the equipment.

Warranty and After-Sales Service

Inquire about the warranty offered on their products. A manufacturer that stands behind their equipment with a solid warranty is more likely to produce reliable products.

Consider the availability and responsiveness of their after-sales service. This is crucial for addressing any issues that may arise during the operation of the welding rotator.

Certifications and Compliance

Ensure that the manufacturer complies with industry standards and certifications. This may include ISO certifications, CE markings, and other relevant quality assurance standards.

Price and Value for Money

While cost is a factor, don't compromise on quality. Consider the overall value for money by assessing the quality, features, and support services offered by the manufacturer.

Delivery Time and Lead Times

Inquire about the delivery time for their welding rotators. Timely delivery is important to keep your projects on schedule.

Global Presence and Distribution

Consider whether the manufacturer has a global presence or distributors in your region. This can be beneficial for obtaining spare parts and support services.

Environmental and Safety Considerations

Check if the manufacturer adheres to environmental and safety regulations in their manufacturing processes. This is especially important in industries where safety and environmental standards are strict.

By carefully evaluating these factors, you can make an informed decision when choosing a welding rotator manufacturer that best suits your needs and ensures the success of your welding projects.

No. 1 Intersection of Chuangye Avenue and Weilai Avenue,

Yiyang County,Luoyang City, Henan Province, China

+86 400-0379-069

Copyright © 2023 An Automated Welding and Cutting Equipment Manufacturer Focusing on Welding Column Boom and Welding Rotator | All Rights Reserved Technical support: ShangXian