Here's a breakdown of the welding process for wind tower welding rotators:

Plate Rolling: Large steel plates (often exceeding 80mm thick) are rolled into cylindrical "cans."

Longitudinal Welding: Individual cans are seam-welded along their length. This often involves manipulators and column-and-boom systems.

Circumferential Welding (where rotators are key): Once individual cans are formed, they are aligned and joined to each other with circumferential welds to form tower sections. This is the primary application for welding rotators. Rotators hold and rotate the heavy, cylindrical sections, allowing a stationary welding head (typically on a column and boom manipulator) to perform the circular weld.

Flange Welding: Flanges are attached to the ends of sections, also by circumferential welds, for on-site assembly.

Door Frame Welding: Door frames are welded, typically using mechanized flux-cored or metal-cored arc welding.

Submerged Arc Welding (SAW): This is the dominant welding process for both longitudinal and circumferential seams in wind tower fabrication.

High Deposition Rate: SAW can deliver extremely high weld metal deposition rates and the necessary heat for the thick steel used in wind towers.

Automation: SAW is highly adaptable to automation, which is critical for consistent quality and productivity on large, repetitive welds.

Multi-wire SAW: To further increase productivity, multi-wire SAW systems (e.g., twin arc, tandem arc, tandem twin arc) are commonly used, where multiple welding torches feed the same weld pool.

Flux Shielding: The arc is submerged under a blanket of granular flux, protecting the weld pool from atmospheric contamination. This also makes it less susceptible to environmental factors like wind.

Orientation: SAW typically requires gravity to hold the weld metal and flux in place, meaning the parts must be reoriented (e.g., rotated by rotators) to maintain a flat or horizontal welding position.

Other Processes (for specific applications):

Gas Metal Arc Welding (GMAW or MIG) and Flux Cored Arc Welding (FCAW): Used for various applications, including door frame welding or in conjunction with SAW for certain passes.

Electrogas Arc Welding (EGW): A high-efficiency vertical automatic welding process used for thick plates, especially in offshore wind power generation facilities. A newer variant, SESLA, offers advantages like minimal spatter and fumes and excellent wind resistance.

Narrow Gap Welding: Applied to reduce weld volume, utilizing special flat welding heads and single or tandem wire heads.

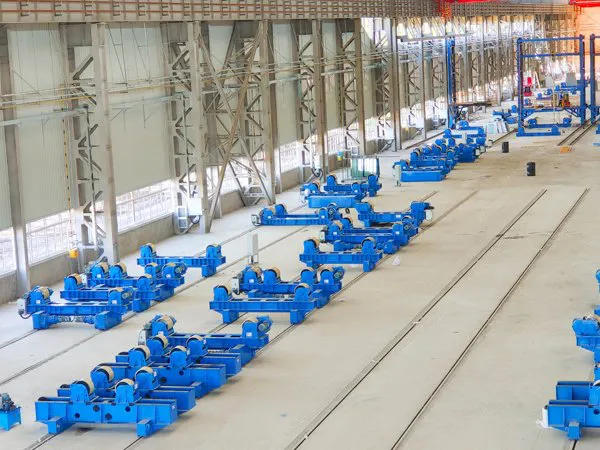

Precise Rotation: Welding rotators (also known as turning rolls) use wheels to align and rotate cylindrical workpieces, such as the "cans" of a wind tower, at a uniform and controlled speed.

Types of Rotators:

Conventional Rotators: Simple, solid, and widely used for internal welding, long seam welding, surface treatment, and internal equipment installation.

Self-Aligning Rotators (SAR): Predominantly used in round seam welding (circumferential welds) due to their ability to provide highly stable rotation and automatically center the workpiece.

Anti-Drift Rotators: Specifically designed to prevent sections from drifting during rotation, crucial for maintaining precise alignment during the welding process.

Fit-Up Rotators: Help in precisely aligning two sections (cans) before circumferential welding.

Integration with Automation: Rotators are almost always used in conjunction with other automated welding equipment, such as:

Column and Boom Manipulators: These carry the SAW welding head to the joint. The rotator rotates the can, while the SAW head remains stationary for circumferential welds, or moves longitudinally for seam welds.

Laser Seam Tracking and Camera Systems: Integrated with rotators and manipulators to ensure the joint is accurately tracked and welded, allowing operators to monitor the process remotely and reduce fatigue.

PLC/HMI (Programmable Logic Controller with Human-Machine Interface): Provides real-time control over welding variables and rotator movement, enabling precise adjustments and optimization of the welding process.

Thick Steel: Wind towers are made from very thick steel, requiring high deposition rates and careful control of heat input to prevent defects. SAW, especially multi-wire SAW, addresses this.

Size and Weight: The enormous size and weight of wind tower sections necessitate heavy-duty rotators and material handling systems.

Weld Quality: Any weld defects can be very costly to repair and compromise structural integrity. Automation, precise control, and appropriate welding consumables are crucial for high-quality welds.

Environmental Conditions (for on-site welding or in harsh environments): While most tower fabrication is done in workshops, specific applications (like joining sections on-site or for offshore/Arctic conditions) may face challenges from cold, wind, and vibrations. Specialized welding robots are being developed to handle these extremes.

In essence, welding rotators are fundamental to the automated and efficient production of wind towers, providing the necessary positioning and rotation for the demanding welding processes involved, primarily Submerged Arc Welding, to ensure high-quality and productive fabrication.

No. 1 Intersection of Chuangye Avenue and Weilai Avenue,

Yiyang County,Luoyang City, Henan Province, China

+86 400-0379-069

Copyright © 2023 An Automated Welding and Cutting Equipment Manufacturer Focusing on Welding Column Boom and Welding Rotator | All Rights Reserved Technical support: ShangXian