Performing daily maintenance on a wind tower welding production line is critical for ensuring safety, weld quality, equipment longevity, and maximizing uptime. A breakdown can halt the entire production process, which is incredibly costly.

Core Principles of Daily Maintenance

Safety First, Always: All maintenance activities must begin with safety. This includes using proper Personal Protective Equipment (PPE) and strictly following Lockout/Tagout (LOTO) procedures for any task that involves potential energy release.

Operator Involvement: The machine operators are the first line of defense. Train them to perform these daily checks as part of their pre-shift routine. They are most familiar with the normal sounds and operations of their equipment.

Cleanliness is Key: A clean work area and clean equipment make it easier to spot leaks, cracks, or other potential issues.

Consistency and Documentation: Perform these checks at the same time every day (e.g., at the start of the first shift). Use a checklist (digital or paper) to log findings, track issues, and ensure nothing is missed.

This checklist is broken down by the major components of a typical production line, which often uses Submerged Arc Welding (SAW) for the main longitudinal and circumferential seams.

This is a high-level visual inspection before starting any equipment.

General Housekeeping:

Floor is clear of obstacles, trip hazards, and spills (especially oil or grease).

All safety guards, barriers, and emergency stops are in place and unobstructed.

Adequate lighting in all work areas.

Utilities:

Check for any visible leaks from air lines or hydraulic hoses.

Ensure main power and compressed air supplies are on and at correct pressures.

Perform these checks at each primary welding station (e.g., L-seam gantry, girth welder). Ensure equipment is de-energized and LOTO procedures are followed where necessary.

A. Welding Manipulator (Column & Boom)

Visual Inspection:

Check for loose bolts or components on the column, boom, and travel carriage.

Inspect chains, belts, or lead screws for proper tension and signs of wear.

Check hydraulic lines and fittings for leaks.

Cables & Hoses:

Inspect the cable management system (cable track/chain) for damage.

Check welding cables, control cables, and hoses for cuts, abrasions, or kinks. Ensure they move freely without snagging.

B. Welding Head & Wire Feeder

Consumables (The most frequent source of issues):

Contact Tip: Check for wear (ovality) and spatter buildup. Replace if worn or clogged.

Wire Spool: Ensure the wire spool is properly seated and the brake tension is set correctly (not too loose, not too tight).

Drive Rolls: Check that drive rolls are clean, have the correct groove size for the wire, and have proper tension. A quick jog of the wire feed should show smooth, consistent feeding without slipping or deforming the wire.

Wire Guides/Liners: Ensure they are clear of debris.

Mechanical:Check that the welding head is securely mounted.

Verify any cross-slide or motorized adjustment mechanisms are clear and operational.

C. Submerged Arc Flux Handling System

Flux Hopper:

Check flux level in the main and head-mounted hoppers. Refill as needed from the drying oven.

Ensure the flux delivery valve/gate operates correctly.

Flux Recovery System:

Check that the vacuum nozzle is positioned correctly and is not clogged.

Empty the slag container/separator.

Check vacuum hoses for clogs or holes. Briefly turn it on to confirm suction.

Check and clean the filter if accessible.

D. Welding Power Source & Controller

Visual Inspection:

Check that all cable connections (especially the ground/work lead) are tight and free of corrosion. A loose ground is a common cause of poor weld quality.

Ensure cooling fans are unobstructed and operational. Listen for unusual noises.

Check digital displays on the controller/HMI for any error codes.

Function Check:

Verify that the control pendant buttons and emergency stop are working correctly.

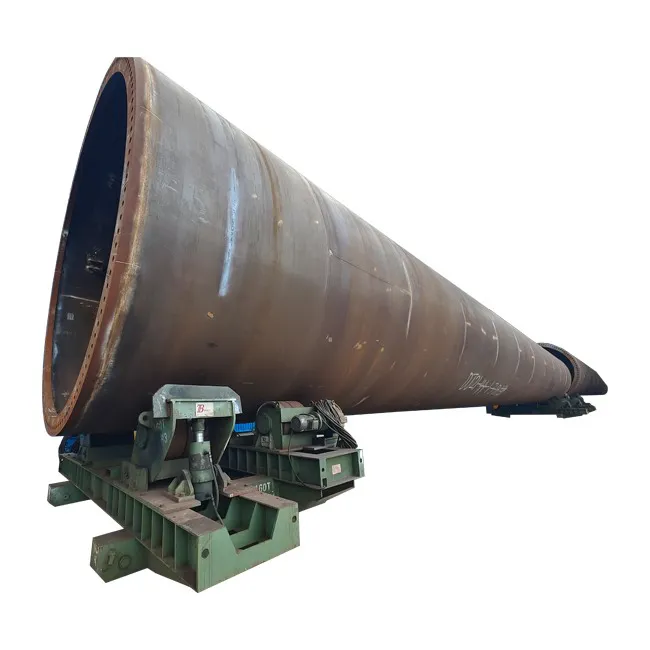

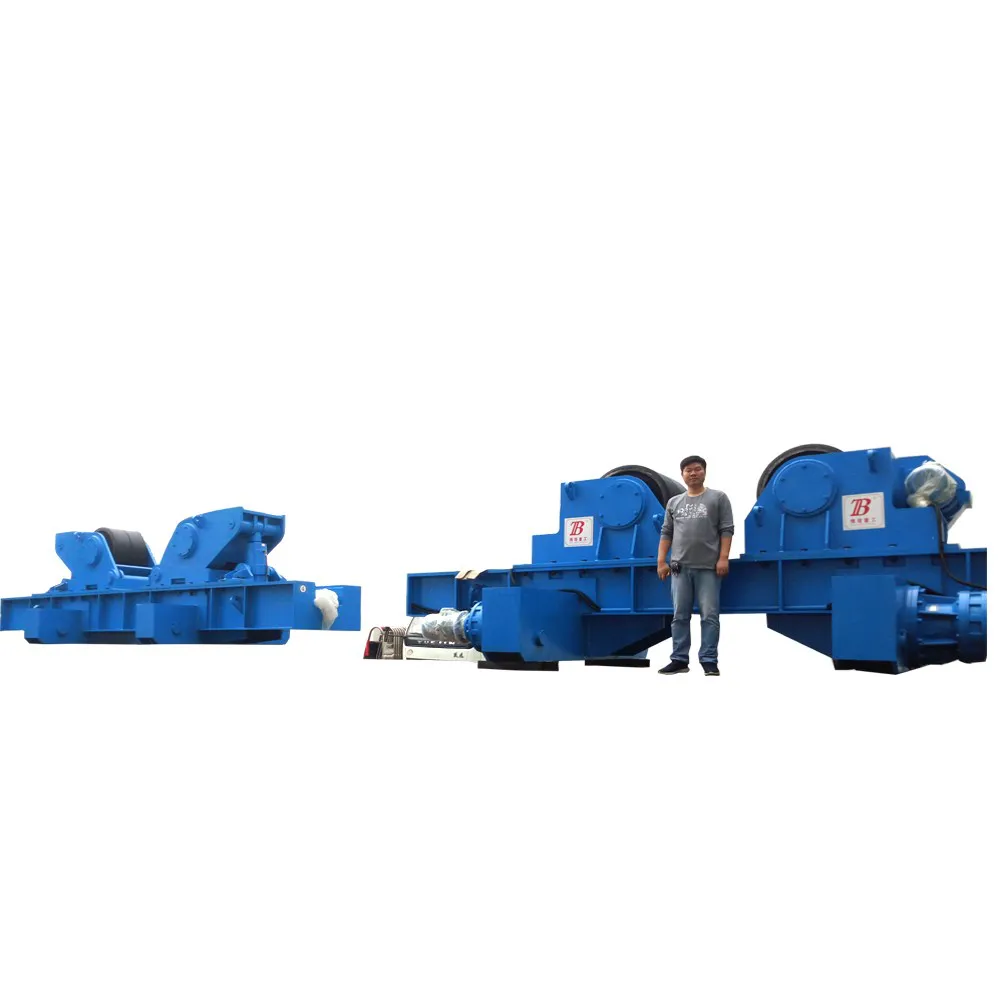

E. Turning Rolls / Rotators

Visual & Mechanical:

Inspect wheels for excessive wear, chunking, or embedded debris (like weld spatter).

Check that all wheels rotate freely.

Listen for unusual noises from drive motors or gearboxes (grinding, whining).

Ensure the grounding path through the rotators is intact and functioning (if applicable).

Controls:

Verify the control pendant (forward, reverse, speed control) is functioning properly.

Clean Up:

Clean spatter from the welding head, fixtures, and turning rolls.

Sweep or vacuum excess flux and slag from the work area.

Shutdown:

Retract the welding head to a safe "home" position.

Turn off the wire feed and power source.

Cover any open flux hoppers to prevent moisture absorption overnight.

Report:

Log all maintenance checks in the daily logbook.

Report any identified issues, faults, or "near misses" to the shift supervisor or maintenance department immediately. Don't leave a problem for the next shift to discover.

By implementing this structured daily routine, you will significantly reduce unexpected downtime, improve weld consistency, and create a safer working environment on your wind tower production line.

No. 1 Intersection of Chuangye Avenue and Weilai Avenue,

Yiyang County,Luoyang City, Henan Province, China

+86 400-0379-069

Copyright © 2023 An Automated Welding and Cutting Equipment Manufacturer Focusing on Welding Column Boom and Welding Rotator | All Rights Reserved Technical support: ShangXian