Offshore wind towers are critical components of modern renewable energy infrastructure, providing the foundation for wind towers installed in marine environments. Their manufacturing process is highly specialized, requiring high-quality wind tower welding production line,precision engineering, advanced welding techniques, and strict quality control to ensure long-term performance in harsh offshore conditions. From steel plate rolling and section welding to surface treatment and final assembly, each stage of production is designed to deliver structural stability, corrosion resistance, and the ability to withstand extreme wind and wave loads. Understanding the manufacturing process of offshore wind towers helps highlight the complexity, technological innovation, and stringent standards behind the development of these essential structures in the global transition to clean energy.

The primary material for wind towers is high-strength steel. Large steel plates, often several meters wide and thick, are sourced from specialized steel mills. These plates undergo initial inspection for defects and are then cut to the required dimensions using laser or plasma cutting machines.

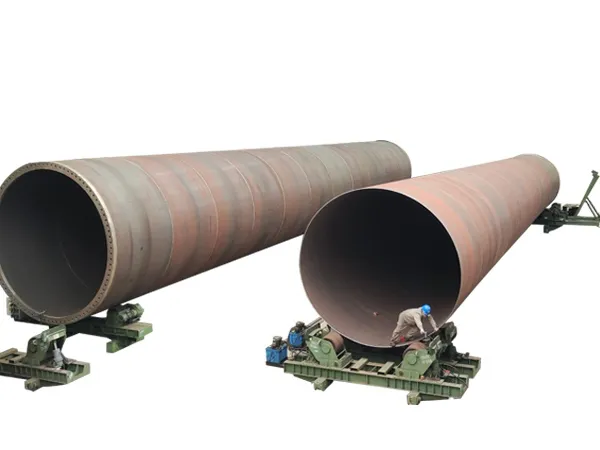

The flat steel plates are then rolled into cylindrical or conical sections. This is achieved using large rolling machines that gradually bend the steel into the desired curvature. The rolling process requires precision to ensure the correct diameter and seamless fit for subsequent sections.

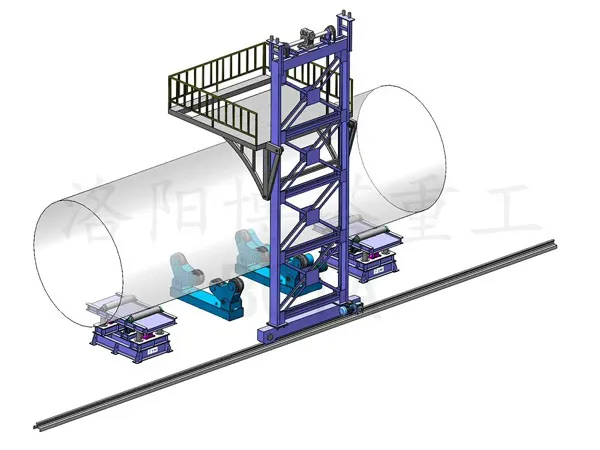

Once rolled, the edges of each steel section are welded together to form a complete cylinder. This is typically done using automated submerged arc welding (SAW) or gas metal arc welding (GMAW) processes, which provide strong and consistent welds. Multiple weld passes may be required due to the thickness of the steel.

Several individual cylindrical or conical sections are then assembled to form larger tower sections, often called "cans." This involves fitting the ends of the rolled and welded sections together and performing circumferential welds. Again, automated welding techniques are commonly used to ensure high-quality, continuous welds.

Flanges, which are large, thick steel rings, are welded to the ends of each tower section. These flanges are critical for connecting the tower sections together at the installation site using high-strength bolts. The welding of flanges requires extreme precision to ensure perfect alignment.

Before final assembly, internal components such as platforms, ladders, and electrical cabling pathways are installed within each tower section. These provide access for maintenance personnel and facilitate the routing of power cables.

To protect the steel from corrosion in the harsh marine environment, the tower sections undergo extensive surface treatment. This typically involves shot blasting to remove rust and impurities, followed by the application of multiple layers of protective coatings, including primers and topcoats. The painting process is critical for the tower's lifespan.

Throughout the entire manufacturing process, rigorous quality control checks are performed. This includes visual inspections, ultrasonic testing of welds, magnetic particle inspection, and dimensional checks to ensure all specifications are met.

The individual tower sections are then ready for transport. For very large towers, sections may be transported separately and assembled at the port before being shipped to the offshore wind farm site.

Offshore wind towers are essential components of wind turbines, serving as the structural support that connects the foundation to the nacelle and blades. Because these towers must withstand harsh marine environments, extreme winds, and dynamic loads, their manufacturing process requires advanced engineering, strict quality control, and precise fabrication techniques.

Compared to onshore wind towers, offshore versions are typically larger, thicker, and designed for higher durability due to the challenging conditions at sea. The entire process integrates advanced welding technology, automated production systems, and strict safety standards to ensure long service life and reliability of the tower.

No. 1 Intersection of Chuangye Avenue and Weilai Avenue,

Yiyang County,Luoyang City, Henan Province, China

+86 400-0379-069

Copyright © 2023 An Automated Welding and Cutting Equipment Manufacturer Focusing on Welding Column Boom and Welding Rotator | All Rights Reserved Technical support: ShangXian