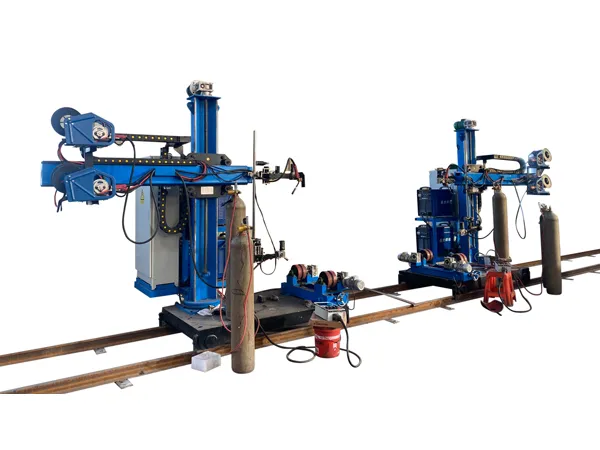

Welding manipulators are essential pieces of equipment in automated and semi-automated welding operations, designed to provide precise control over welding torches for consistent and high-quality welds. However, like all industrial machinery, welding manipulators are subject to wear, mechanical failures, and electrical issues over time. Knowing how to diagnose and repair a welding manipulator is crucial for maintaining production efficiency, ensuring workplace safety, and minimizing downtime.

Repairing a welding manipulator involves diagnosing common mechanical, electrical, and welding-related issues.

Before starting repairs, observe symptoms to narrow down the issue:

Mechanical Issues: Jerky movement, misalignment, excessive vibration, or unusual noises.

Electrical Issues: Power failure, motor not responding, or erratic control behavior.

Welding Issues: Poor arc stability, inconsistent wire feed, or irregular torch movement.

Check Rails & Guides

Issue: Misalignment or wear causing jerky movement.

Solution:

Clean and lubricate linear guides.

Adjust or replace worn-out rails/bearings.

Inspect Drive Mechanism

Issue: Faulty gears, belts, or chains.

Solution:

Tighten or replace loose/damaged belts/chains.

Grease gears or replace if teeth are worn.

Column & Boom Stability

Issue: Excessive vibration or wobbling.

Solution:

Tighten bolts and structural joints.

Check for cracks in the boom and repair with welding if needed.

Motor Not Running

Check:

Power supply (fuses, breakers, voltage).

Motor brushes (for DC motors) or windings (for AC motors).

Solution:

Replace blown fuses or faulty wiring.

Repair or replace the motor if damaged.

Encoder/Servo Issues

Issue: Incorrect positioning or erratic movement.

Solution:

Recalibrate the encoder.

Replace faulty servo drives or feedback sensors.

Control Panel Malfunction

Issue: Unresponsive buttons or display errors.

Solution:

Reset the controller or update firmware.

Replace damaged control boards if necessary.

Wire Feed Problems

Issue: Inconsistent wire feeding or jamming.

Solution:

Clean or replace the wire feed liner.

Adjust feed roller tension.

Torch Movement Issues

Issue: Misaligned or shaky torch.

Solution:

Recalibrate the manipulator’s path programming.

Check and tighten torch mounting brackets.

Arc Stability Problems

Issue: Poor weld quality due to erratic arc.

Solution:

Check ground connections.

Inspect welding cables for damage.

To avoid frequent repairs:

Lubricate moving parts regularly.

Inspect electrical connections for corrosion.

Calibrate the manipulator periodically.

Clean dust and debris from rails and motors.

If the issue involves:

Complex CNC or servo system errors.

Major structural damage (e.g., cracked boom).

High-voltage electrical faults beyond basic troubleshooting.

By following these steps systematically and prioritizing safety, you can effectively repair many common issues with welding manipulators. Always refer to the specific manual for your equipment.

No. 1 Intersection of Chuangye Avenue and Weilai Avenue,

Yiyang County,Luoyang City, Henan Province, China

+86 400-0379-069

Copyright © 2023 An Automated Welding and Cutting Equipment Manufacturer Focusing on Welding Column Boom and Welding Rotator | All Rights Reserved Technical support: ShangXian