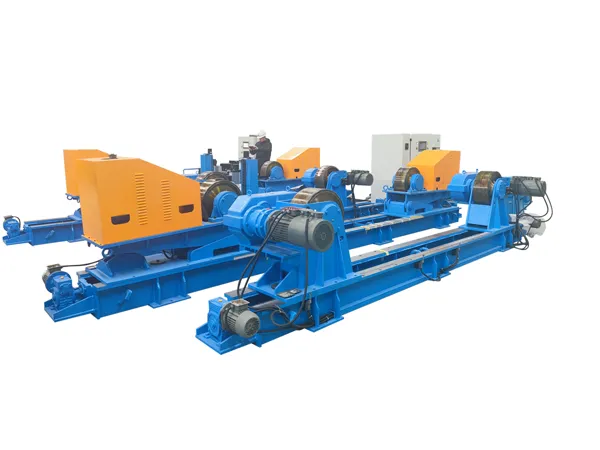

Welding rotators have become a core piece of equipment in modern fabrication workshops, particularly in industries dealing with tanks, pipes, pressure vessels, and cylindrical components. A reliable rotator not only improves weld uniformity but also increases safety and overall production efficiency.

However, welding rotator prices vary significantly depending on configuration, capacity, and technical features. For buyers—whether manufacturers, contractors, or workshop owners—understanding these cost drivers is essential to making a smart, long-term investment.

This 2026 guide provides a deeper look into the factors influencing welding rotator pricing, current market trends, and practical advice that can help you optimize both budget and performance.

Welding rotators have a wide pricing spectrum depending on load capacity, feature set, and manufacturing origin. Below is a general reference range seen in the current market(2025–2026):

▸ Light-duty rotators (1–20 tons)

Price range: USD 800 – 6,000

Used for small tanks, pipes, laboratory fabrication, and light industrial tasks.

▸ Medium-duty rotators (20–100 tons)

Price range: USD 6,000 – 18,000

Popular among pressure-vessel workshops, machinery factories, and general steel fabrication.

▸ Heavy-duty rotators (100–500 tons)

Price range: USD 18,000 – 80,000

Built for large industrial boilers, chemical tanks, offshore pipes, wind-power towers.

▸ Ultra-heavy rotators (500+ tons)

Price range: USD 80,000 – 200,000+

Customized builds with dual-drive systems and advanced automation.

Note: Price differences also depend on brand reputation, country of origin, and customization level.

2.1 Load Capacity & Workpiece Dimensions

Load capacity remains the strongest cost driver. As load increases, manufacturers must use

Larger gearboxes

Higher torque motors

Reinforced structural frames

Precision bearings

These upgrades significantly increase production cost.

Industry Insight:

Workshops often underestimate their future capacity needs. Choosing a rotator with 20–30% higher capacity than current demands reduces replacement risk and ensures safety for oversized workpieces.

2.2 Motor Type, Power, and Control System

• AC Motors

More economical

Suitable for general welding tasks

Lower precision

• DC Motors

Better speed control

Strong torque output

Ideal for automated welding

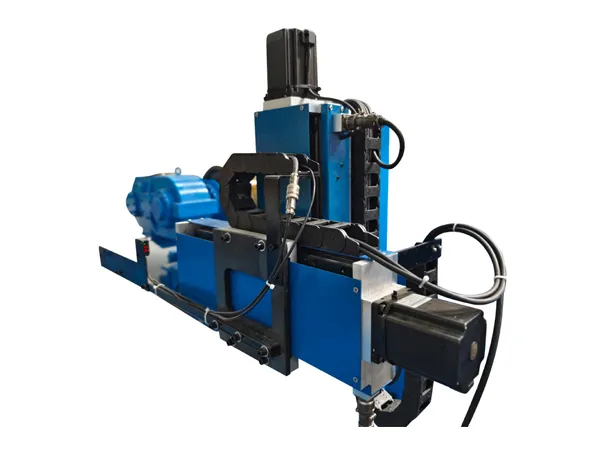

• Servo & Variable Frequency Drive (VFD) Systems

Premium-grade

Used in automated welding lines

Higher cost but better reliability

Expert Suggestion:

If your workshop handles stainless steel, aluminum, or precision welding, DC or servo systems significantly improve weld consistency and reduce rework.

2.3 Roller Material and Configuration

Rollers come in different materials:

Polyurethane rollers:

Protect workpiece surface

Quieter operation

Higher cost

Steel rollers:

Lower price

Best for heavy-duty loads

Less surface protection

Roller count also affects price

2-roll: economical, for general use

4-roll: better stability, widely used in high-end fabrication

Adjustable multi-roll: used for irregular cylinders

Real Workshop Scenario:

Wind tower manufacturing often uses self-aligning 4-roller rotators to handle diameter changes without manual adjustment.

2.4 Welding Rotator Frame & Build Quality

Material selection influences both lifespan and price.

Higher-priced models often feature:

Q345B or higher-grade structural steel

Laser-cut components for accuracy

CNC-machined shafts

Sealed bearings to reduce maintenance

Why this matters:

A well-built rotator reduces machine vibration, which directly affects weld uniformity.

2.5 Speed Control Options and Automation Level

Basic rotators offer fixed rotation speeds.

High-end models include:

Variable-speed digital control

Auto synchronization with welding column & boom

Remote control operation

PLC automation

For smart workshops:

Automation reduces manpower demands and aligns with modern Industry 4.0 welding standards.

2.6 Additional Features that Increase Price

Wireless remote controller

Automatic overload protection

Digital torque display

Hydraulic elevation or tilting

Synchronized twin-rotator systems

Workpiece centering system

These don’t apply to every workshop but dramatically enhance efficiency in high-volume production.

Step 1: Define Your Workpiece Parameters

Weight (minimum, maximum)

Diameter range

Surface material

Length

Step 2: Identify Your Welding Process

Manual welding

Submerged arc welding

TIG/MIG

Automated welding

Step 3: Evaluate Long-Term Usage, Not Just Current Jobs

Many workshops purchase rotators only to upgrade within 2–3 years due to increased production needs.

Recommendation:

Choose a rotator model that supports future expansion.

Step 4: Compare Materials & Electrical Components

European/Japanese electrical components cost more but offer better stability.

Step 5: Evaluate Supplier Capability

Consider:

Welding rotator manufacturing history

Quality certifications

On-site factory audit (if possible)

After-sales support & spare parts availability

Welding rotators are widely used in:

Pressure vessel fabrication

Petrochemical industry

Food & beverage tank manufacturing

Wind tower sections

Boiler workshops

Pipe production lines

Shipbuilding and offshore engineering

Example:

A pressure vessel manufacturer may use both self-aligning rotators and conventional rotators to handle different tank diameters without frequent manual adjustment, improving production efficiency by 25–40%.

Q1: How much weight should my welding rotator support?

Choose a capacity 20–30% above your heaviest workpiece.

Q2: Do I need polyurethane or steel rollers?

Polyurethane: stainless steel, painted surfaces

Steel: heavy-duty carbon steel cylinders

Q3: What is the typical lead time for a welding rotator?

Most manufacturers deliver within 15–35 days, depending on customization.

Q4: Are welding rotators compatible with automation systems?

Yes, mid-to-high-end models support PLCs, welding manipulators, and column-and-boom welding systems.

Q5: How often should a welding rotator be maintained?

Routine maintenance every 1–3 months depending on workload.

When selecting a welding rotator, avoid focusing solely on price. Instead, evaluate:

Practical load requirements

Roller material suitability

Motor precision and torque

Supplier engineering experience

Long-term maintenance cost

Safety performance under full load

A well-chosen rotator enhances welding precision, reduces operational risk, and significantly improves production efficiency.

No. 1 Intersection of Chuangye Avenue and Weilai Avenue,

Yiyang County,Luoyang City, Henan Province, China

+86 400-0379-069

Copyright © 2023 An Automated Welding and Cutting Equipment Manufacturer Focusing on Welding Column Boom and Welding Rotator | All Rights Reserved Technical support: ShangXian