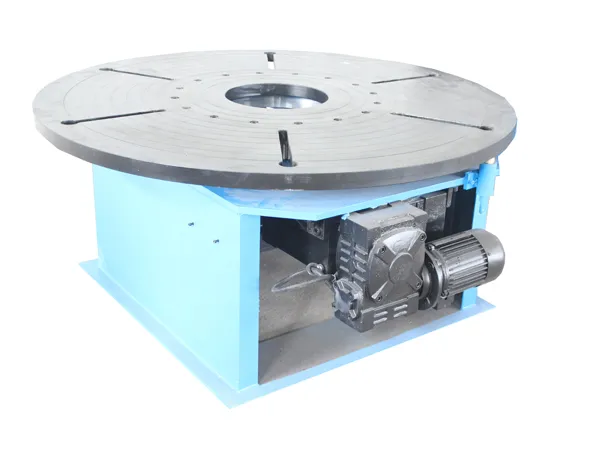

The welding turntable is a versatile tool used in various welding applications to improve productivity, enhance weld quality, and ensure operator safety.

Purpose and Benefits

The welding turntable, also known as a rotary welding positioner, serves a critical role in welding processes by enabling controlled rotation of the workpiece or welding gun. This rotation facilitates access to all sides of the workpiece without manual repositioning, thereby streamlining welding operations. Some key benefits of using our welding turntable include:

Enhanced Weld Quality: The consistent rotation provided by the turntable ensures uniform heat distribution and deposition of weld material, resulting in high-quality, defect-free welds.

Increased Productivity: By eliminating the need for manual repositioning of the workpiece, our welding turntable reduces downtime and allows for continuous welding, leading to faster completion of projects.

Operator Safety and Comfort: The ergonomic design of the turntable minimizes strain on operators by eliminating the need for repetitive manual handling of heavy or awkward workpieces. This helps prevent fatigue and reduces the risk of musculoskeletal injuries.

Operating our welding turntable is straightforward, but it requires proper setup and adherence to safety procedures. Here's a brief overview of the basic operation:

Setup: Securely mount the workpiece or welding gun onto the turntable, ensuring proper alignment and balance to achieve optimal welding results.

Power On: Activate the turntable's power supply and control panel, following any specific startup procedures outlined in the user manual.

Adjust Rotation Speed and Direction: Use the control panel to adjust the rotation speed and direction according to the welding requirements and specifications of the workpiece.

Perform Welding: Initiate the welding process using the appropriate welding equipment (e.g., MIG, TIG, or stick welder), while the turntable rotates the workpiece. Monitor the welding operation to ensure proper weld bead deposition.

Shutdown: After completing the welding task, power off the turntable and any associated equipment, and safely remove the finished workpiece.

While our welding turntable offers significant advantages, it's essential to prioritize safety during operation. Here are some critical safety precautions to observe:

Always wear appropriate personal protective equipment (PPE), including welding helmets, gloves, and safety glasses, to protect against arc flash, sparks, and other hazards.

Familiarize yourself with the location and operation of emergency stop buttons and other safety features on the turntable.

Avoid reaching into the rotating area while the turntable is in operation, and ensure that loose clothing, jewelry, or other items cannot become entangled in moving parts.

By following these safety guidelines and the instructions outlined in this manual, you can safely and effectively utilize our welding turntable to achieve superior welding results.

No. 1 Intersection of Chuangye Avenue and Weilai Avenue,

Yiyang County,Luoyang City, Henan Province, China

+86 400-0379-069

Copyright © 2023 An Automated Welding and Cutting Equipment Manufacturer Focusing on Welding Column Boom and Welding Rotator | All Rights Reserved Technical support: ShangXian