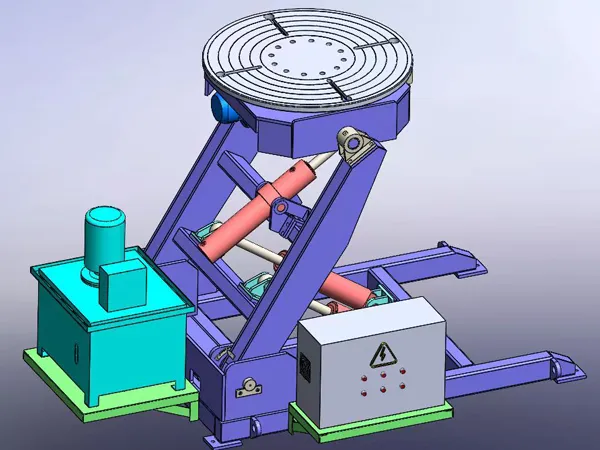

The welding turntable is mainly composed of a turn table, a large high-strength rotary support, a high-torque reducer, a frequency conversion braking motor, a conductive device, and an electrical control system. The rotary speed of the rotary table is variable frequency stepless speed regulation.

The welding turntable is mainly composed of a turn table, a large high-strength rotary support, a high-torque reducer, a frequency conversion braking motor, a conductive device, and an electrical control system. The rotary speed of the rotary table is variable frequency stepless speed regulation. The rotary table is composed of a rotary table and 8 outriggers.

A conductive device is installed between the box-shaped beam and the workbench, thereby forming a conductive loop of the welding ground wire. Insulation treatment is adopted between the conductive device and the beam to prevent the bearing from being over-charged and causing damage to equipment components.

The conductive rod in the conductive device adopts copper rod. The contact surface between the conductive column and the workbench is polished smooth, but not painted, so as to ensure good electrical conductivity and prevent the copper rod from sticking to the workbench after overheating.

In response to the increasing load requirements of most customers, BOTA has developed a hollow rotation method, which can automatically adjust the angle of the workpiece through the drive of the motor. Angle adjustment without dead angle, precision

Fine, large load, effectively avoiding the error between the space and the workpiece, the interface standard of the platform, it is very convenient to carry out manual control through the motor and transmission parts, and at the same time, it can be realized through the connection of the control system

Electric control, the motor can be a servo motor or a stepper motor. Able to carry out data signal transmission during work and accurately complete work goals.

Rotation Control

Variable speed control to adjust the rotation speed according to the welding requirements.

Directional control to rotate the workpiece in both clockwise and counterclockwise directions.

Workpiece Holding

Equipped with a chuck or a table surface to securely hold the workpiece in place.

May include additional clamps or fixtures to stabilize irregularly shaped objects.

Tilt Functionality

Some models come with tilt capabilities, allowing the table to be angled for better access to different parts of the workpiece.

Typically ranges from 0 to 90 degrees, providing flexibility in positioning.

Weight Capacity

Designed to support various weight capacities, from lightweight components to heavy industrial parts.

Important to choose a turntable that can handle the maximum weight of the workpieces being welded.

Foot Pedal Control

Often includes a foot pedal for hands-free operation, enabling the welder to focus on the welding torch.

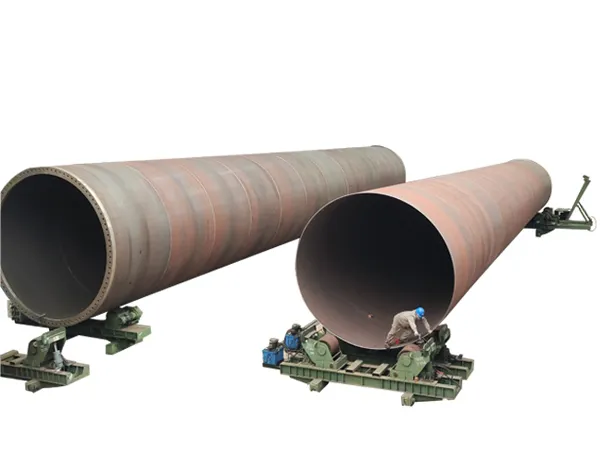

Pipe Welding: Ideal for welding circular seams on pipes and tubes.

Flange Welding: Useful for attaching flanges to pipes or other cylindrical objects.

Industrial Manufacturing: Widely used in automotive, aerospace, and other industries requiring precision welding on round components.

When selecting a welding turntable, consider the following factors:

Size and Weight Capacity: Ensure the turntable can accommodate the dimensions and weight of your workpieces.

Speed Range: Choose a model with a suitable speed range for your welding process.

Tilt Capability: Determine if you need a tilting feature based on the complexity of your welds.

Control Options: Look for user-friendly controls, including foot pedals and digital displays.

Build Quality: Opt for durable materials and construction to ensure long-term reliability.

Hydraulic Fit-Up Welding Rotator

Bench Top Elevating Welding Positioner

Flip & Turn Welding Positioner

Hydraulic Tilting Welding Positioner

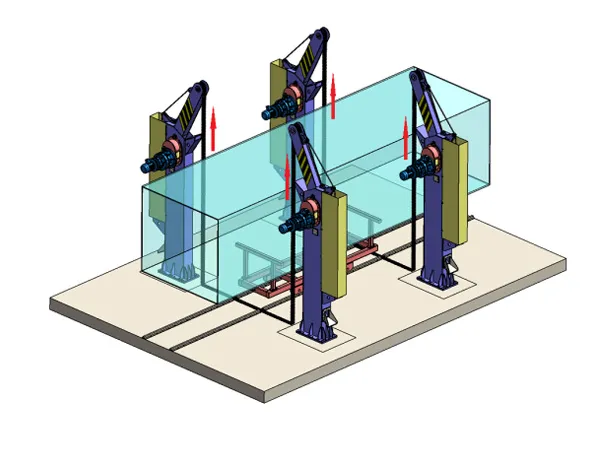

Double Column Welding Positioner

3 Axis Welding Positioner

Front & Back Flipping Welding Positioner

Chain Overturning Welding Positioner

Skyhook Welding Positioner

No. 1 Intersection of Chuangye Avenue and Weilai Avenue,

Yiyang County,Luoyang City, Henan Province, China

+86 400-0379-069

Copyright © 2023 An Automated Welding and Cutting Equipment Manufacturer Focusing on Welding Column Boom and Welding Rotator | All Rights Reserved Technical support: ShangXian