Welding positioner is a general-purpose, high-end welding equipment mainly for circular seam welding. It can be equipped with argon arc welding machine (with or without wire filling), molten gas shielded welding machine (C02/MAG/MIG welding machine), plasma welding machine and other welding power sources, and can be combined with other units to form an automatic welding system. Three types of commonly used welding positioners!

Outrigger Welding Positioner

Structural features and performance of the extension wall welding positioner The rotary table is installed on the outrigger, and the outrigger generally rotates at an angle relative to a certain inclined axis, and the position of the inclined axis is mostly fixed, but some can be less than 100° Slope up and down within the range. The machine has a large displacement range and good operation adaptability, but the overall stability is poor. Its scope of application is the overturning and displacement of small and medium-sized workpieces below 1t. It is widely used in manual welding. Most of them are driven by electric motors, with a load capacity of less than 0.5t, and are suitable for small and rare reversing displacements. There are also hydraulically driven ones, which have a large load-bearing capacity and are suitable for weldments with small structural dimensions but large self-weight.

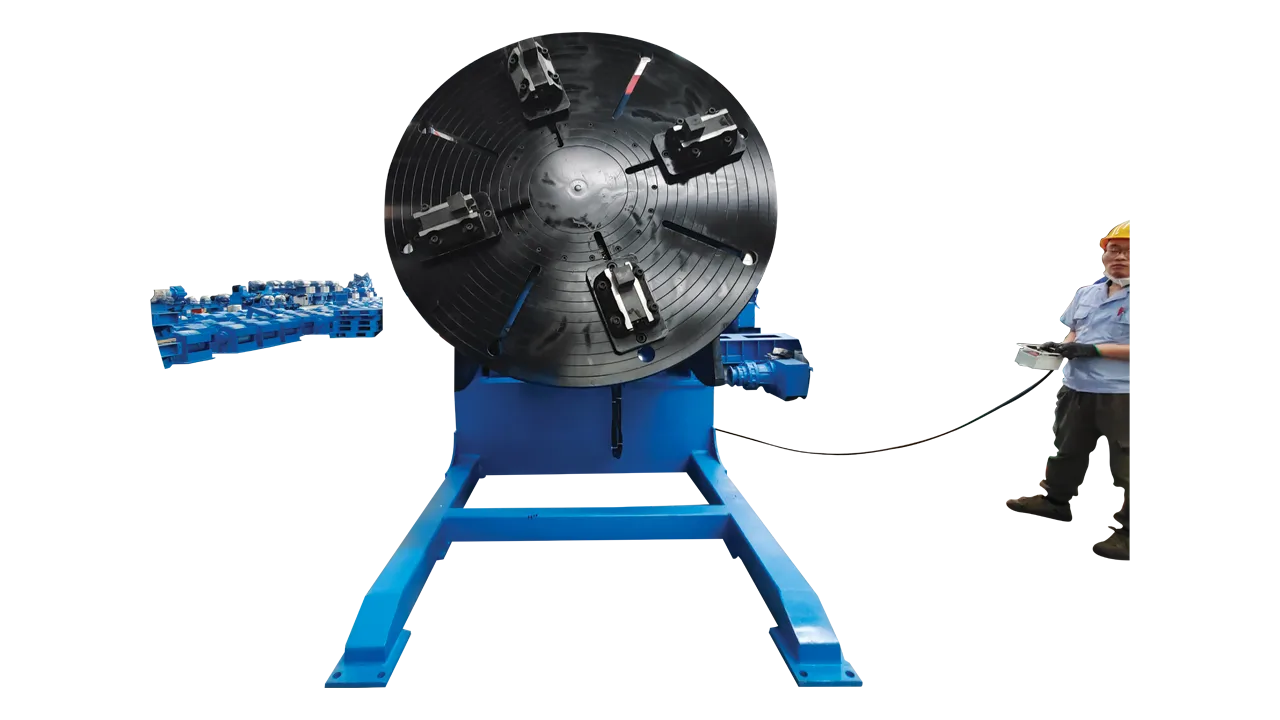

Seat Welding Positioner

The workbench of seat type welding positioner has a degree of freedom of overall turning. The work can be turned over to the ideal welding position for welding. In addition, the workbench has a degree of freedom of rotation. This kind of positioner has been produced in series and is mainly used for welding some tubes and discs. The side of the worktable is supported on the inclined shafts on both sides by the slewing mechanism, the worktable rotates at the welding speed, and the inclined side passes through the sector gear or the hydraulic cylinder, and the inclined side is mostly tilted at a constant speed within the range of 140°. The machine has good stability, and generally does not need to be fixed on the ground, so it is easy to move. Its scope of application is the turning and shifting of workpieces from 1 to 50 tons. It is a widely used structural form at present and is often used in conjunction with telescopic arm welding manipulators. Seat type positioner The seat type positioner is a device that makes the welding seam in a horizontal or boat-shaped position through the rotation or tilt of the worktable. The table rotation adopts frequency conversion without speed regulation, and the table is driven to tilt by sector gears or hydraulic cylinders. It can realize joint control with manipulator or welding machine. Three configurations are optional for the control system: button digital control, switch digital control and switch relay control. This product is used in the welding of various shafts, discs, cylinders and other rotary workpieces. It is the most widely used structural form at present.

Seat type positioner can be divided into seat type positioner and small seat type positioner according to different loads

The machine has good stability and generally does not need to be fixed on the foundation. It is easy to move and is suitable for the turning and shifting of 0.5~50t weldments. It is the structural form with large output, specification and wide application. It is often used in conjunction with a telescopic arm welding manipulator or an arc welding robot.

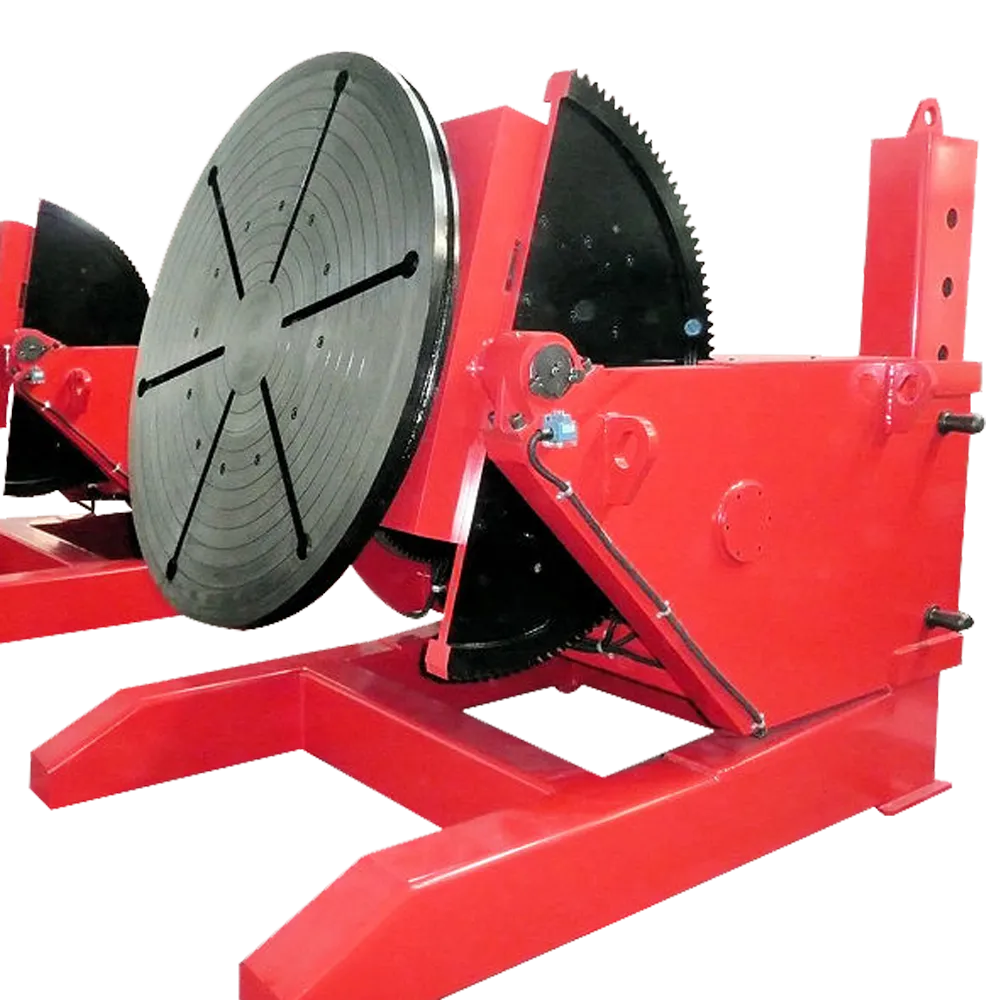

Two seat welding positioner

The two-seat welding positioner is a positioning machine that integrates the functions of turning and turning. Turning and turning are respectively driven by two shafts. In addition to turning around its own axis, the worktable holding the workpiece can also tilt or turn around another axis. It can adjust the welds at various positions on the weldment to the level It is suitable for the welding of frame type, box type, disc type and other non-long workpieces.

The workbench is seated on the "U"-shaped frame and rotates at the required welding speed. The "U"-shaped frame is seated on the machine bases on both sides, and mostly rotates around the horizontal axis at a constant or required welding speed. This machine not only has good overall stability, but also if the design is proper, after the workpiece is placed on the workbench, the center of gravity of the tilting motion will pass through or approach the tilting axis, so that the tilting driving torque will be greatly reduced. Therefore, heavy positioners often use this kind of structure. Its scope of application is the turning and shifting of heavy and large-sized workpieces over 50t, and it is often used in conjunction with large-scale portal welding manipulators or telescopic arm welding manipulators.

The two-seat welding positioner is suitable for the turning and shifting of large-size weldments over 50t. In welding operations, it is often used in conjunction with large portal welding manipulators or telescopic arm welding manipulators.

No. 1 Intersection of Chuangye Avenue and Weilai Avenue,

Yiyang County,Luoyang City, Henan Province, China

+86 400-0379-069

Copyright © 2023 An Automated Welding and Cutting Equipment Manufacturer Focusing on Welding Column Boom and Welding Rotator | All Rights Reserved Technical support: ShangXian