The production process of a wind tower production line involves several stages, from the manufacturing of individual components to the assembly of the complete wind tower structure.

Material Preparation:

Raw Materials: The main materials used in wind tower production typically include steel plates and sections. These materials are sourced from steel mills and undergo quality inspection upon arrival at the production facility.

Cutting: Steel plates and sections are cut to the required dimensions using cutting machines such as plasma or flame cutting equipment. Precise cutting ensures that the components fit together accurately during assembly.

Component Manufacturing:

Flanges and Base Plates: Flanges and base plates are fabricated from steel plates using cutting, bending, and welding processes. These components provide the foundation and attachment points for the tower sections.

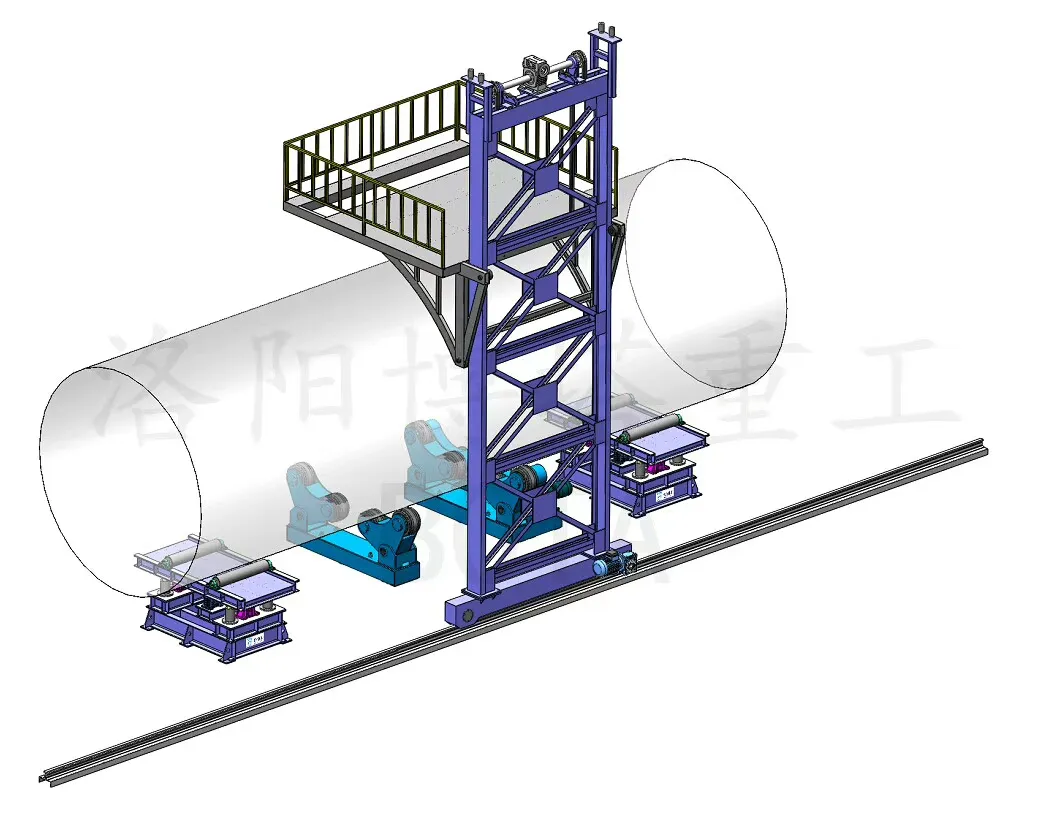

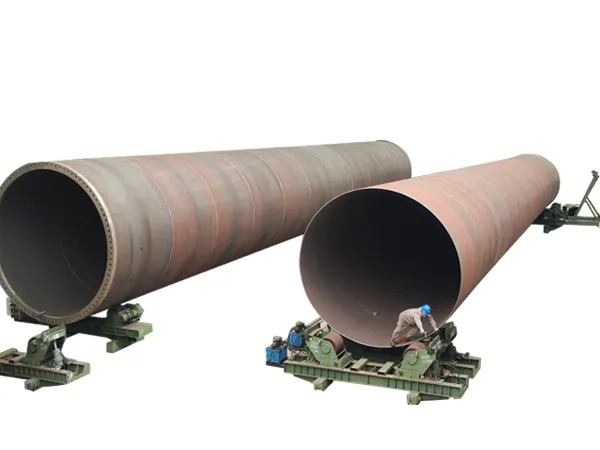

Tower Sections: Tower sections are manufactured by rolling and welding steel plates into cylindrical or conical shapes. Automated welding processes such as submerged arc welding (SAW) or gas metal arc welding (GMAW) are used to ensure high-quality welds.

Surface Treatment:

Shot Blasting: After fabrication, the steel components undergo shot blasting to remove any surface contaminants and improve the adhesion of protective coatings.

Priming and Painting: Primers and protective coatings are applied to the steel components to prevent corrosion and ensure long-term durability, especially in harsh outdoor environments.

Tower Assembly:

Tower Segments: The tower sections are assembled by welding them together using specialized welding equipment and techniques. Welding parameters are carefully controlled to meet stringent quality standards and ensure structural integrity.

Internal Components: Internal components such as platforms, ladders, and cable trays may be installed inside the tower during assembly to facilitate maintenance and servicing.

Flanges and Base Plates: Flanges and base plates are welded to the bottom of the tower to provide a secure foundation for installation.

Quality Assurance:

Non-Destructive Testing (NDT): Various NDT techniques such as ultrasonic testing (UT) and magnetic particle testing (MPT) are used to inspect welds and ensure they meet specified standards.

Dimensional Inspection: The assembled tower undergoes dimensional inspection to verify that it meets the required tolerances and specifications.

Transportation and Installation:

Once assembled and inspected, the wind tower sections are transported to the wind farm site for installation. Specialized equipment such as cranes and transport trailers are used to handle and transport the large and heavy tower sections.

Installation crews assemble the tower sections on-site and secure them to the foundation, followed by the installation of the turbine components such as the nacelle, rotor blades, and hub.

Throughout the entire production process, strict quality control measures are implemented to ensure the safety, reliability, and performance of the wind tower structure. Collaboration between engineers, welders, fabricators, and quality assurance personnel is essential to successfully manufacture and install wind towers for renewable energy generation.

No. 1 Intersection of Chuangye Avenue and Weilai Avenue,

Yiyang County,Luoyang City, Henan Province, China

+86 400-0379-069

Copyright © 2023 An Automated Welding and Cutting Equipment Manufacturer Focusing on Welding Column Boom and Welding Rotator | All Rights Reserved Technical support: ShangXian