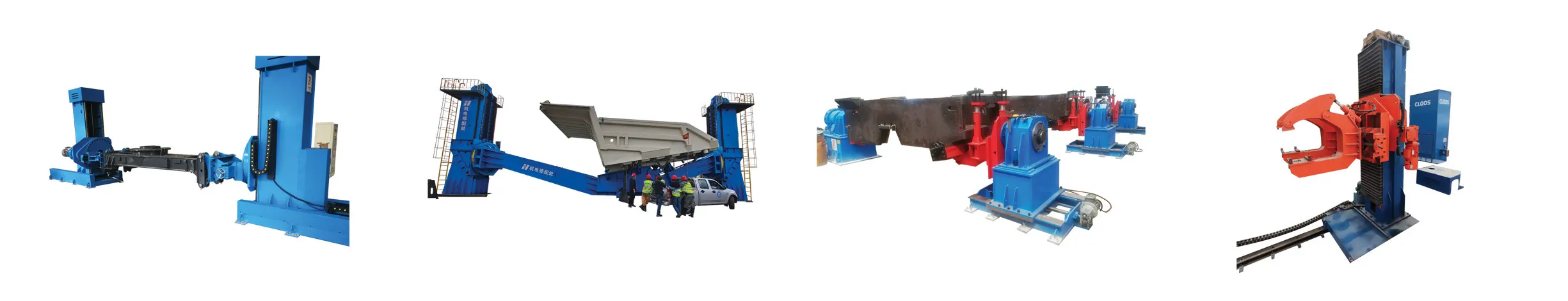

It is a combination of a head and tail and a turntable. Especially for very heavy parts that require a lot of handling. It consists of two Welding Positioner BHBS with a beam between them, which has a motorized turning plate in the center. It is custom-made equipment, widely used in hydroelectric turbines given the complexity of their welding. Capacities from 50 to 500 tons, although they are manufactured according to the client's needs.

It is a combination of a head and tail and a turntable. Especially for very heavy parts that require a lot of handling.

It consists of two Welding Positioner BHBS with a beam between them, which has a motorized turning plate in the center.

It is custom-made equipment, widely used in hydroelectric turbines given the complexity of their welding.

Capacities from 50 to 500 tons, although they are manufactured according to the client's needs.

Welding Positioner is one of the auxiliary machines to adjust the position of the workpiece, headstock and tailstock welding positioner divided into fixed type and lifting type.

Headstock and tailstock welding positioner is divided into fixed type and lifting type. The headstock and tailstock standard positioner clamps the super-long workpiece at both ends, and it can be rotated and lifted by electric power. Install the workpiece at the lowest possible position, and raise it with the workpiece loaded,

Descending, turning. Since it can be installed in a place where work is relatively easy, safety, productivity, and workability are improved. The head and tail frame positioner prepares 9 standard models for selection in order to correspond to different loading workpieces of customers. In order to correspond to the workpieces of different customers, a variety of standard models are available for users to choose. As an option, there is a cross-beam type, a standard travel on the tail, and a single-side clamp can also be used with a single body of the nose (drive side).

No. 1 Intersection of Chuangye Avenue and Weilai Avenue,

Yiyang County,Luoyang City, Henan Province, China

+86 400-0379-069

Copyright © 2023 An Automated Welding and Cutting Equipment Manufacturer Focusing on Welding Column Boom and Welding Rotator | All Rights Reserved Technical support: ShangXian