The hydraulic butt welding rotator is specially designed for cylinder assembly operations, which can significantly reduce the time and labor required for cylinder alignment and jacking during assembly operations, thereby saving costs and can withstand harsh conditions working environment.

The hydraulic butt welding Welding Rotator is specially designed for cylinder assembly operations, which can significantly reduce the time and labor required for cylinder alignment and jacking during assembly operations, thereby saving costs and can withstand harsh conditions working environment. The Welding Rotator with Hydraulic Lifting.

It is used to complete the calibration and docking work of the cylinder. The whole machine is installed on the same guide rail as the electric Traveling Welding Rotator for slewing, and the left and right positions can be adjusted according to welding needs.

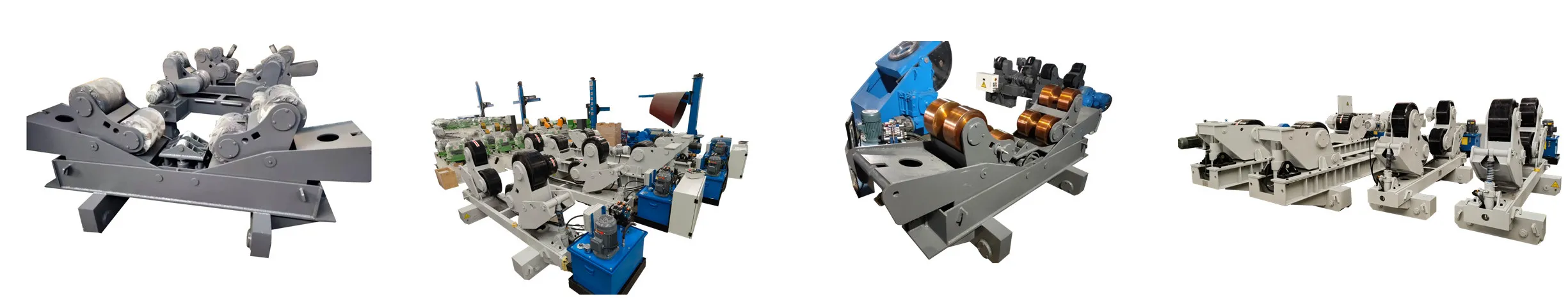

Conventional style hydraulic fit-up welding rotator is mainly used for the fitting-up between cylinders. There are two types of side-pull type and top-up type to choose from. The side-pull type adjusts the relative distance between the cylinders by adjusting the center distance of the rollers. Position, suitable for light-duty cylinders, the side top is to adjust the relative position between the bodies by adjusting the center height of the rollers, suitable for heavy-duty cylinder rollers, polyurethane wheels and steel wheels can be used, the rotation speed of the rollers can be adjusted steplessly by frequency conversion, and the remote control is used Control, with practical and reliable, stable rotation, convenient operation and so on.

Self adjusting style hydraulic fit-up welding rotator is mainly used for the Fit-up between cylinders. There are two types of side-pull type and top-up type to choose from. The side-pull type adjusts the relative distance between the cylinders by adjusting the center distance of the rollers. Position, suitable for light-duty cylinders, the side top is to adjust the relative position between the bodies by adjusting the center height of the rollers, suitable for heavy-duty cylinder rollers, polyurethane wheels and steel wheels can be used, the rotation speed of the rollers can be adjusted steplessly by frequency conversion, and the remote control is used Control, with practical and reliable, stable rotation, convenient operation and so on.

1. Hydraulic fit up rotator is composed of base, roller assembly, hydraulic cylinder, hydraulic control system and control box.

2. Each set of the hydraulic fit up rotator is composed of a driving frame and a driven frame. Each roller frame is equipped with two sets of hydraulic cylinders to drive the roller assembly system. The hydraulic cylinder is used to adjust the position of the roller assembly or move a certain The roller assembly is used for the alignment of the workpiece.

3. The drive of the roller frame is driven by a three-phase asynchronous motor through a frequency converter, and after being decelerated by a reducer, the roller is driven to work to realize speed control.

4. The two roller frames are respectively placed on the walking trolley, one of which is equipped with a motor to drive the wheels through the reduction box; the other set of walking trolley is in the form of driven walking, and the workpiece is placed in the hydraulic group. On the roller frame of the team, the workpiece is transported away by the driving force of the main traveling trolley.

5. The hydraulic system is uniformly supplied with oil by the hydraulic pump station to each hydraulic cylinder, and the hydraulic cylinders can be operated and controlled separately, and each hydraulic cylinder can independently drive a roller assembly.

No. 1 Intersection of Chuangye Avenue and Weilai Avenue,

Yiyang County,Luoyang City, Henan Province, China

+86 400-0379-069

Copyright © 2023 An Automated Welding and Cutting Equipment Manufacturer Focusing on Welding Column Boom and Welding Rotator | All Rights Reserved Technical support: ShangXian